![]() . . .

. . .

To Finish or Not to Finish. That is the question.

Scroll way down for Prowell’s WoodRX pre-finish offerings

Factoid: There are no exterior wood finishes– be it oil, stain, varnish, or paint–that will prolong the life of your Prowell product by a single day. Your finishing decisions are purely aesthetic and entirely subjective. We know this from 47 years of revisiting our project sites from Duluth to Miami to Santa Barbara.

1) The correct species of wood matters.

—a): Western Cedar is inherently stable, which means the dimensional changes it experiences between the seasons is minimal.

—b): Western cedar is equipped through millenniums of evolution with a plasma, or tannin oils, that deters the infestation of an ecosystem of bacterial fungus.

—c): Our standing orders from the mills specify the normal clear, kiln-dried demands. But more so, vertical grain and a growth ring count of at least 20 per inch.

——-c1): Vertical grain boards are less likely to cup, warp, or twist than face grain board

—- –c2): 20 growth rings simply means that the tree is not harvested prematurely, which in turn means the tannins have fully matured and fiber between early harvest tree is less baby fat than developed, stable wood fiber.

2): The design of the products themselves accounts for a level of dimensional change and drainage that must be considered with any wood assembly fully exposed to the elements. The wood must breath.

3): The complexity of wood joinery, which in turn allows the cedar to breath feeling for decades and decades, without being inhibited by nails, screws, bolts, and metal fasteners.

Exterior Wood Finishes—Stains, oils, varnishes, and paint. Reviewing your options

Exterior Wood Finishes—Stains, oils, varnishes, and paint. Reviewing your options

Choosing the best finish for outdoor projects

Prowell’s products are fully exposed to the elements in a way unknown to the wood siding of a house or a front door or a garage door, etc, and consequently expecting them to accept any finish with the same forgiveness and lifeline is leashing yourself to a maintenance schedule that is at odds with nature, and a rather painful recurring expense. We’ll review the various options for the best exterior wood finish below, with their advantages and disadvantages.

OPTIONS:

The below options require that the cedar be fully exposed to the elements for 2-3 weeks prior to applying your outdoor finishing product. The cedar will acclimate from the Pacific NW of its heritage to wherever you are. This applies particularly to non-penetrating finishes–paint, etc–where the paint , etc may not expand and contract at the same rate as the gate and the result is bubbles and checks.

EXTERIOR CLEAR OIL PENETRATING WOOD FINISHES

1 year timeline.Can be applied immediately upon receipt of gate

Properties:

Earth tones only. Matte finish

Clear Oil finishes are absorbing, which is good. Oil-Based.

Advantages:

1) Oil enhances the color of the wood.

2) If maintenance is neglected, oil does not crack or peel. So it can be re-oiled long after it has grayed out, and the color returns.

Disadvantages:

1) The best exterior oil finishes require multiple initial coats. The more the better.

2) Oil finishes, at best, last a year.

TWO-PART FINISHES WITH TOP COATS

3-5 years timeline. Cedar must acclimate 2-3 weeks prior to coverage

Properties:

Two-part finishes begin with an absorbing coat that provides the pigment, or tint. Essentially an oil finish.

The second follow-up coat a day later is non-absorbing, laying over the Part-1 to provide the sheen. Oil-Based.

Advantages:

1) A little luster is nice. Front entry doors have luster. Dining room tables have luster. Some lips have luster.

2) Hand-prints, etc can be wiped clean.

Disadvantages:

1) There is no exterior wood finish that is impermeable to the moisture in the air–humidity, dew, fog. Wood exposed to the elements is going to expand and contract regardless. Sealing finishes, however, inhibit the cedar’s ability to breath freely.

2) The top coat and its sheen, if neglected, will ultimately crack and peel–particularly for southern-facing exposure to the sun. RPotential cracking and peeling requires scraping and sanding prior to refinishing. Prowell products often have intricate patters, making it difficult to scrape and sand in the event the normal maintenance schedule is ignored.

3) 2-part finishes have a lifeline of 2+ years. i.e. they require frequent maintenance.

MARINE SPAR EXTERIOR VARNISH

1-2 years timeline. Cedar must acclimate 2-3 weeks prior to coverage

Properties

Better known as Man O’ War Spar varnish, the thick, molasses-like signature high-gloss varnish for classic mahogany and teak wood boats. Oil-Based.

Advantages: None

Disadvantages:

1) Unless you are a classic boat enthusiast who has nothing better to do with your days than spend them refinishing your Prowell products, this option is to be avoided at all costs.

2) Severe checking and peeling of neglected

3) Requires annual maintenance.

4) Long, slow dry time. This means you have to continually check for runs if finishing the gates vertically. It also means that while the finish is drying, it collects dust particles like flypaper.

SEMI-TRANSPARENT EXTERIOR WOOD STAIN

5+- years timeline. Can be applied immediately upon receipt of gate

Properties

Absorbing stains that provide color pigment and sealer in one coat. Oil-Based

Advantages:

1) With pigmented color at your disposal, you can match the trim or house body color with a translucent likeness.

2) An absorbing product, meaning it penetrates the wood fiber and won’t crack or peel. If neglected, it simply wears away and the cedar eventually weathers to a natural gray. The cedar is allowed to breath freely.

3) Easy to apply and can be refinished at any time.

Disadvantages:

1) Semi-transparent finishes often absorb with inconsistent results, due to the various densities of the cedar within a single board. For most manufacturers, two coats is discouraged, as the first coat seals and a second coat fails to penetrate, leaving a splotchy finish where portions of the cedar absorbs and other portions do not.

SOLID-BODY PIGMENT EXTERIOR STAINS

7+- years timeline. Cedar must acclimate 2-3 weeks prior to coverage

Properties

A paint-like consistency that lays on the wood, as opposed to penetrating finishes. Oil and water based.

Advantages:

1) Wide range of pigmented color to choose from.

2) Although checking or peeling are potential threats if neglected beyond the timeline, the threat is minimal.

3) Gives a slight sheen , somewhat less than semi-gloss paint.

Disadvantages:

1) No real disadvantages other than the cedar must be fully exposed to the local climate for 2-3 weeks prior to finishing. So if it’s winter when your gate is delivered, and it gets wet while being exposed for it 2-week acclimation, you must allow it to dry out prior to applying the stain lest you seal in any accumulated moisture. 2-3 days of dry weather usually does that.

EXTERIOR PAINT

7-10 years timeline. Cedar must acclimate 2-3 weeks prior to coverage

Properties

Good quality exterior paint such as Benjamin Moore provide the longest lifeline of any finish. A layered finish that does not absorb into the cedar.

Advantages:

1) A perfect match to the preferred color.

2) Long lasting, with a consistent, even color.

3) Wipeable surface. Easy to clean off smudges, etc

Disadvantages:

1) If neglected, it peels and checks and becomes unsightly, not unlike the siding of your house with the exception that the gate/fence, etc are fully exposed to the elements, hence a slightly shorter lifeline. If ignored, requires scraping and sanding before re-painting.

2) It will last almost as long as the paint on your house, but not quite. Unlike the front door or the siding of your house facing one direction only, the gate is exposed on 360 degrees.

3) We’ve learned that in in areas of exceptionally high humidity (Hawaii, southern Florida, etc), or exceptionally dry climates (Phoenix, Palm Springs, etc), painted finishes provide the most durable finishes, and with the least amount of maintenance.

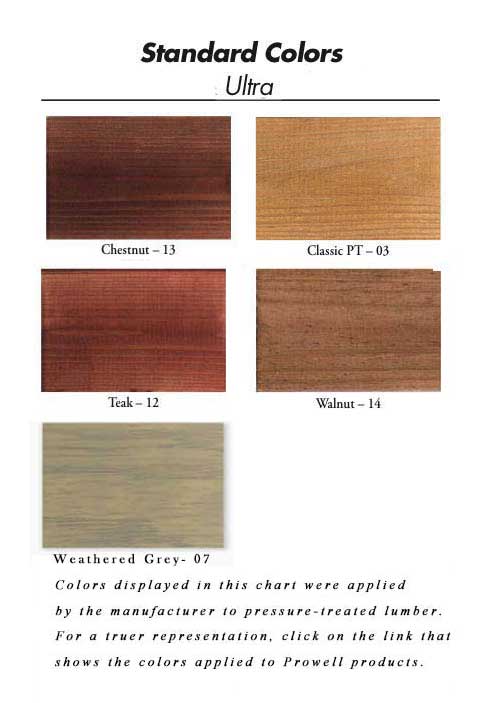

WOODRX EXTERIOR SEMI-TRANSPARENT ABSORBING FINISH

7-8 yr timeline in temperate climates. 5-7 years in high humidity or dry climates.

Properties

A non-solvent, absorbing finish. Earth tone pigments only.

Advantages:

1) Provided by Prowell as a pre-finish option

2)As a water-base exterior wood finish, WoodRX penetrates deeper into the cedar fiber than oil-based products, resulting in a longer lifeline.

2) If the timeline passes and maintenance is neglected, fresh coats can be applied with no prep to the existing cedar. Otherwise it will gradually fade and the cedar will consequently weather to a gradual gray.

3) Water-based. meaning it dries very quick. Second coat can be applied within an hour.

4) No solvent fumes to ingest.

Disadvantages:

1) Because it dries so fast, applying with a brush is not advisable. WoodRX sells a pump sprayer that is more effective than brushing, although the best results are acquired with professional spray equipment. (The posts themselves can be applied with a brush, as the brush strokes are straight and all the grain runs the same direction)

2) Only a few earth tone colors available. Check the link below to see the various pigments on our products.

3) Requires TWO industrially sprayed coats. (The second coat is important)

When, and when not, to Finish:

When, and when not, to Finish:

To many organic landscapes, a weathered gate or fence is the preferred aesthetic. Sites and properties designed in such a manner where products such as Prowell’s are more about the landscape than the architecture of the residence. Painting or staining hard scapes such as fences and gates, etc on these sites is to attempt to carry the precedent of the architecture of the residence into the expanse of the wilderness. On these sites, it is often preferred to simply allow the products to either weather naturally or opt for a pre-weathered finish, which quickens the weathering sequence from two years to being shipped in such a state.

*See Eco-Wood Treatments

Exterior Wood Finishes with Earth-Tones:

Semi-transparent stains

Within the above aesthetic, there is a distinction between organic wilderness and cultivated wilderness. If the lot is large and the gates and fences extend some distance from the residence and as a perimeter to a carefully maintained landscapes, it is architecturally preferable to finish the products with any of the earth-toned patinas provided by any semi-transparent stain.

Exterior Wood Finishes with Color:

–Paint, Semi-transparent stains, solid-body stains.

If, however, the lot is within a manicured neighborhood and the gates and fence are not only connected physically to the main architecture but in close enough proximity to be viewed as a single entity, the gates and fences are often finished with the same color coding as the primary residence. The house body or trim colors extended into the landscape. As the same finish, or the same patina but with the flat matte of a pigmented transparent stain.

There are those sites when a hardscape of fences and gates are inexorably linked to the architecture of the residence. Smallish lots where the gates, etc adjoin the building and never stray too far to establish an identity apart from the primary architecture itself. They are seen upon first impression as accessories to the building. Such as the front porch railing. So, in these scenarios it is more common to match–or closely match–the hardscape gates and fences to either the house’s sidewall color, or the trim. This is a practice followed with either paint, or color-pigmented stain.

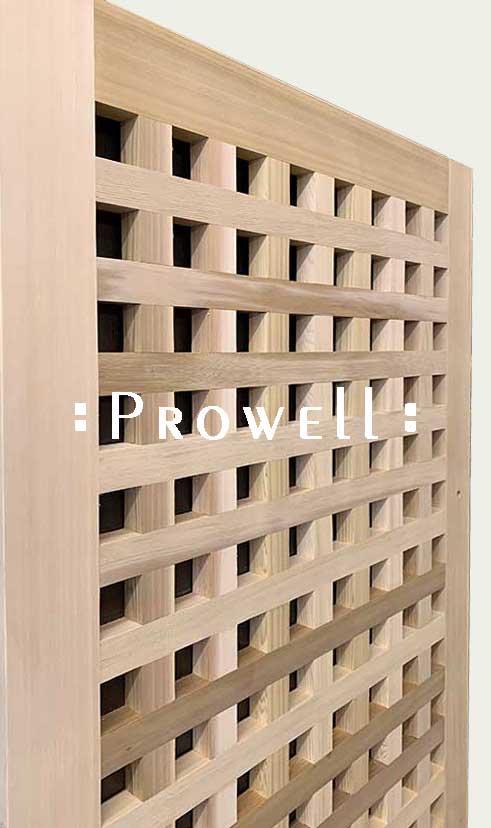

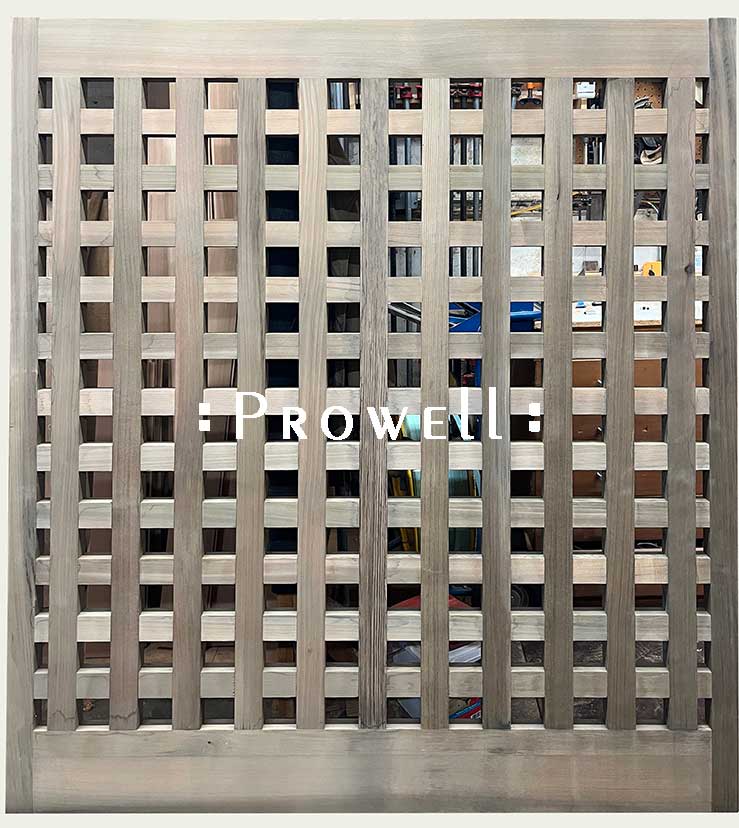

![]() WOODRX ULTRA TRANSAPRENT SEALER / STAIN

WOODRX ULTRA TRANSAPRENT SEALER / STAIN

PRE-FINISHING AVAILABLE BY PROWELL

Prowell has returned to offering WoodRX pre-finishes to your products. Primarily because there are those among you who will opt for a lesser quality finish that results in our products appearing, well…shabby within a year or so. But also because this finish requires two sprayed coats, which is not always easily accomplished by the homeowner.

WoodRX is a non-toxic environmentally-friendly finish for exterior applications. Easy application and quick drying allows for two coats within two hours. (The second coat is extremely important). Because of the quick drying, it also all but eliminates the collection of dust particles gathering between coats. Given its quick drying time, sprayed application is advisable.

Non-toxic, water-based formula. Easy clean-up. Odorless. Quick drying.

*Timeline: 7-8+ years in temperate climates. 5-7+ years elsewhere.

*Click on the WoodRX can on the left for more information, or order through Home Depot’s online store w/ sprayer, or through the manufacturer’s web site: Click Here, and select the color from the drop down menu.

Slightly waxy finish with a satin sheen.

* To view the WoodRX colors on our products

PRICING ESTIMATES

Single Gate……………….$685

Two panels……………….$1,050

Six Panels………………..$2,500

Benches / Swings……. $750

Driveway Gates……….$1,650

*Inquire for pricing on garden gates beyond 47″ width and driveway gates beyond 12′ overall width.

PRE-WEATHERED FINISH

PRE-WEATHERED FINISH

A distressed pre-weathered finish by Eco-Wood creates a chemical reaction to the cedar that results in a mildly aged patina within an hour

As the coloring wears off over the next couple of years, the underlying cedar is gradually exposed to its naturally aged patina.

The advantage is an obvious one: You simply do not have to wait two years for the brightly-milled cedar to become a stately silvery gray.

The application is simple and the results are consistent. Click on the image on the left more information.

Unfinished cedar

With Eco-Wood Pre-weathered finish

![]() Exterior Wood Finishes . . . or Not

Exterior Wood Finishes . . . or Not

NATURALLY WEATHERED GRAY

Leave your products alone to weather and age to an unfettered silvery grey. Their lifeline is far beyond what any warranty can claim and that lifeline will not be extended one day by the application of any exterior wood finish.

Leave your products alone to weather and age to an unfettered silvery grey. Their lifeline is far beyond what any warranty can claim and that lifeline will not be extended one day by the application of any exterior wood finish.

In part because of the species of wood and the grades of that species and the age, or maturity of that grade spec’d by Prowell to insure a minimum number of growth rings stipulating the maturity of the tree at the time of harvest.

But moreover, a thorough understanding of wood and joinery and design. Designing a product that mimics the techniques and species employed by the Japanese and Norwegian temples built in the 3rd and 4th century that stand today! If the wood is allowed to freely breath throughout the year, under any conditions, be it Duluth, MN or Ft Meyers, FL, then that wood is the right wood, the application of finishes is as superfluous as fertilizing a lawn.

Be mindful of the maintenance and cost you’re committed to with a finish. All those little grids and pickets refinished by a finishing contractor every few years and be particularly mindful of those finishes that, when ignored, such as paints and marine varnishes, will crack and peel and require scraping and sanding and on and on.

In the spring of 2013 we visited a site featuring Panel Style #1 originally installed in 1996. Allowed to weather with no detrimental affects to the integrity of the product.

No finish, listed below or above, will prolong the life of a Prowell product by a single day.

This is due to both the species and grade of wood spec’d from the mill, as well as the methodology of both the joinery and design that encourages a stress-free environment for dimensional movement.

Yes, we’re repeating ourselves.

RECOMMENDED TECHNIQUES

Applying your exterior wood finishes

Wood Gates built from even the highest standards of western cedar are not to be confused with decks or house siding or front doors or even garage doors (These have one whole side insulated from the weather, as well as the overhead roof and jambs. Decks and siding planks are fastened to joists or studs every 16″ and exposed on only one face). Prowell’s products are fully exposed to the elements on all six sides. Because our cedar comes from the coastal Northwest, and then inventoried in the shop of coastal Northern California, it will invariably want to breath once it finally leaves the shop and is exposed for the first time to the full climate. Some areas will see more dimensional adjustments than others, such as Florida compared to San Diego.

Prowell’s products are designed to specifically allow the seasonal expansion and contraction of the cedar experienced most dramatically in the first weeks of exposure to the elements. But . . . solid finishes such as paint or solid-body stains or 3-part layered sealants and exterior varnishes will not always cooperate with the wood’s inherent need to acclimate to your specific micro climate. While the cedar is adjusting and breathing during those first weeks, paints and solid stains and marine varnishes will not necessarily stretch with the same pliancy. They may, in 15-20% of the time, even see bubbling and checking and blemished results in the finish.

The solution? If you prefer a painted or solid-body stain finish, it’s best to wait 2-3 weeks once your product arrives and has been installed. Allow it to breath, acclimate itself in its full exposure, and then apply your solid finish to a much higher degree of success. If it rains and takes on moisture during that time frame, allow it to dry in the clear weather for several days prior to applying your finish–lest the absorbed moisture becomes trapped by the finish and has no means of escape.

APPLICATION TIPS

A few notes regarding the application process for exterior finishes.

Although sealing or staining or painting your Prowell product does not prolong the life of the high-grade cedars by a single day, it is often an understandable aesthetic preference.

Excerpted from the Prowell Installation Manuals:

A few application tips:

When applying your finish, start with one side, brushing the bottom rail with the grain and then the vertical stiles with the grain to avoid the brush strokes over-lapping.(This is particularly important with WoodRx, which is water-based and dries very fast). For all horizontal rails, not allowing the brush stroke to dry before brushing the vertical stile. Do not apply stain to the edges of the pickets or upper pattern on this side or the stain will run down the opposite side and leave run marks penetrating the bare wood before you are able to finish the opposite side. For those with solid lower panels, do not stain the edges of your open slots until the back side is addressed. Once you turn to the other side, you can then apply stain to the picket faces and edges, knowing the run-off will not absorb against the already stained surface. Check, when finished, the direction of your brush stroke to smooth out any over-laps.

Spray finishes: All of the above recommended products can be applied with compressed air sprayers for a more even finish without the risk of runs. WoodRX, with it’s faster drying time and water-based formula, is best applied with professional spray equipment. Two coats.

WoodRX sells an accompanying sprayer, available direct from them or through Home Depot (With mixed reviews, we’ll add)

![]() Outdoor Wood Finishes

Outdoor Wood Finishes

PROBLEMS RESULTING FROM CERTAIN FINISHES

WOODRX UTRA

WOODRX UTRA

W e’ll begin with WoodRx. Shown below is an applied WoodRX ‘teak’ finish. Using professional spray equipment by the homeowner and not the little pump sprayer WoodRX offers. And yet we have an uneven consistency, seen most prominently along the bottom rail. This is due to failing to maintain an even motion with the sprayer. Do not hover over over an area, but keep your motion steady. The first coat will absorb deeper in some areas of the cedar fiber than others, but the second coat will even it out to a consistent patina.

TOP COAT FINISHES

A typical gate finished with Sikkens two-part Cetrol-1 and 23-Plus. The top coat (23-Plus) shown only four years later has begun to crack and weather. If not refinished on schedule, the checking and yellowing will only become worse until the process involves scraping, sanding, and stripping.

Illustrating what happens to sealer coats if not meticulously maintained on an annual basis, forever (Think classic wood boat enthusiasts, and their compulsion for everlasting maintenance.).

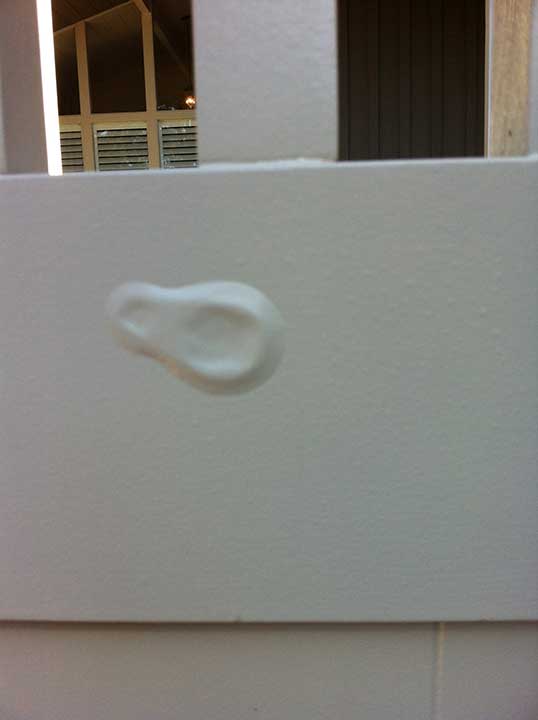

PAINT FINISHES

An example of a product being painted before the wood has fully acclimated to the local climate. This job was in Atlanta, which has a very different climate than the Prowell Shop, therefore resulting in an initial adjustment where the wood swells and shrinks to find the natural stability of Atlanta’s humid environment.

Because paint is not a penetrating finish, it can potentially refuse to stretch with the adjustments of the cedar during the first few weeks on site. The result is a bubbling effect, seen here.

MILDEW ??

Once every few years we get a letter from a concerned homeowner whose gate is host to a blackened discoloring. A fungal bacteria, we assumed. Completely harmless to the cedar fiber and gate, and yet unlike mildew, it wouldn’t wash away using various off-the-shelf products such as OxyClean, mixing bleach and water. We eventually came to realize that the discoloring was a result of the cedar secreting its tannins in a random act we have no control over. Random fibers in boards milled in sequence and arriving in our shop in the same stacked sequence. A rare phenomenon, but recurring over the years and decades such that it warrants this notice. The good news is that it seems to eventually disappear, according to those customers who have been kind enough to share their experiences.

Tannins: The genetic oils in certain species such as cedar and 1st and 2nd growth redwood that accounts for their resistance to bacterial decay. (The earlier a tree is harvested, the less mature, and prevelant, the tannins are. Good regarding the seepage shown, but bad as the tannins are what make cedar so highly resistant to bacterial fungus.).

The below photo illustrates how the sequence of boards, bundled and strapped at the mill, are pulled from our own bins in the same sequence, exhibiting a pattern, or cluster. A cluster of those particular boards with higher resin, or tannin content. A blemish, obviously, that does not begin secreting until exposed to the elements.

SECRETING TANNINS

A nother example, with a slightly different pattern.

WATER MARKS

Lastly, a photo of a new gate left to weather naturally. Less than two weeks from delivery, the cedar shows the expected discoloring from the evening’s dew and fog. Although this is easily removed with light sanding, it should be noted that if such blemishes are of concern, the natural weathering aesthetic might not be right for you. Perhaps a more uniform stained finish is advisable.

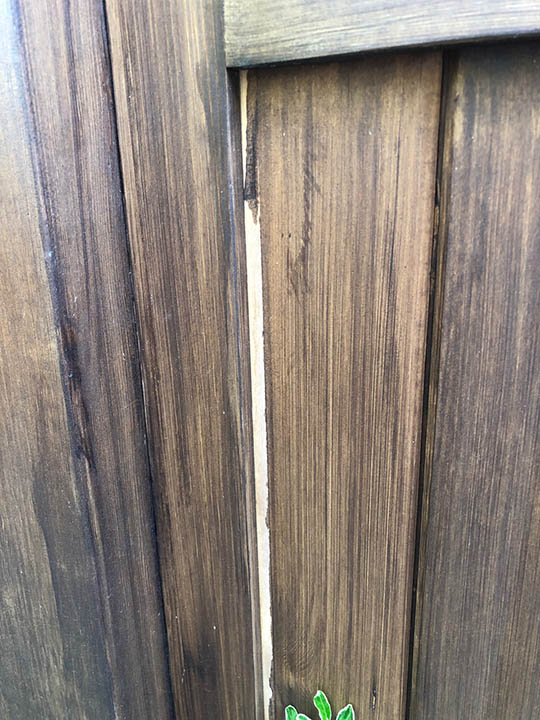

SHRINKAGE

Acommon issue is the lower solid panel delivered or shipped in the wetter season and with the drier season, drying out to where it shrinks enough to expose the unfinished the edges that were formerly concealed within the grooves of the frame stiles. Requiring a touch up. With the return of the wetter climate the panel expands back into the grooves. After a couple of seasons, the cedar has acclimated enough that it no longer breathes to the same degree. In this application, the homeowner applied their finish on site–a Sansin “Weathered-Gray 04”.