Specifications for Exterior Woodworking Joint #9

#9

#9

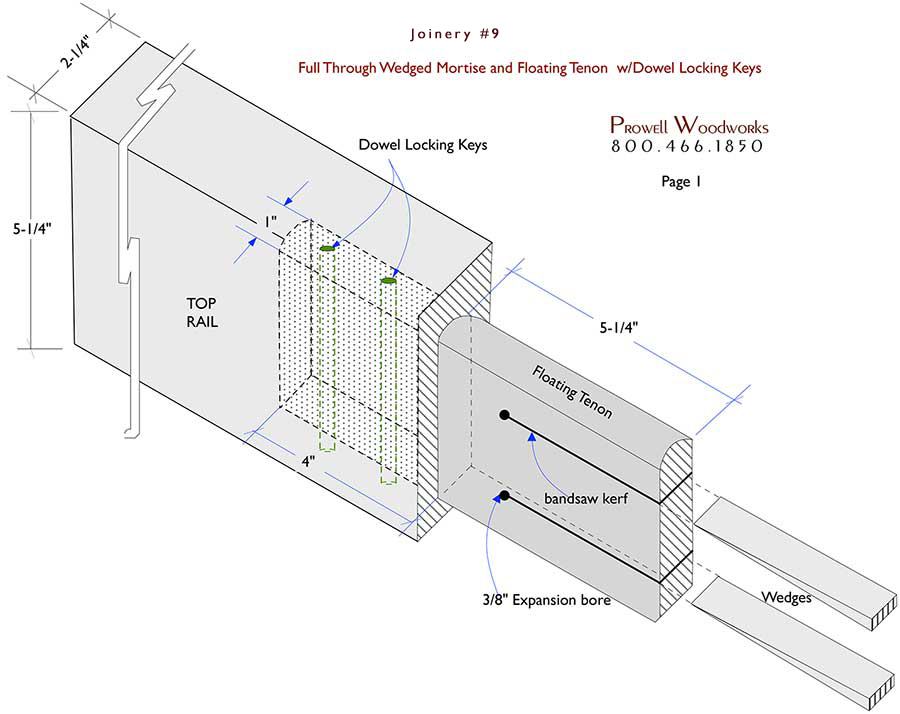

FULL THROUGH WEDGED FLOATING TENON W/DOWEL LOCKING KEYS

A long-winded title for a joint developed as a more efficient solution to the key haunches of Joint #9-1

Click Here for a PDF sketch

JOINERY #9

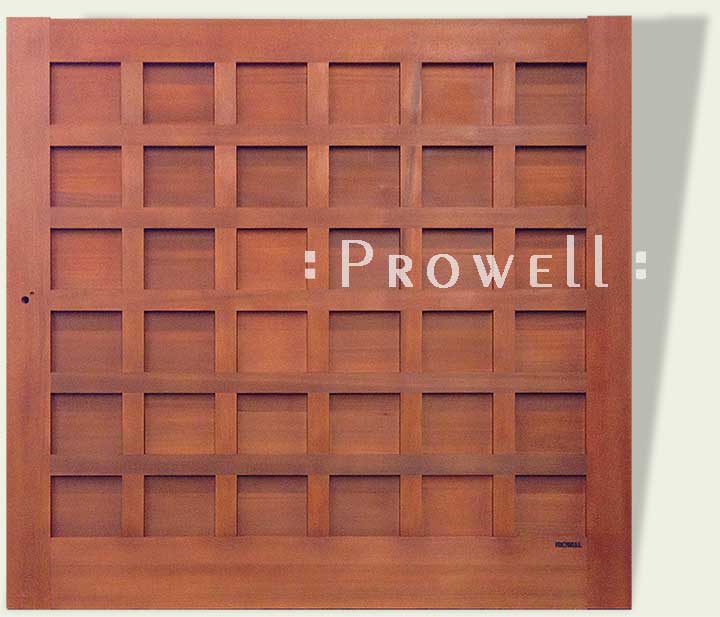

Gate Style #87

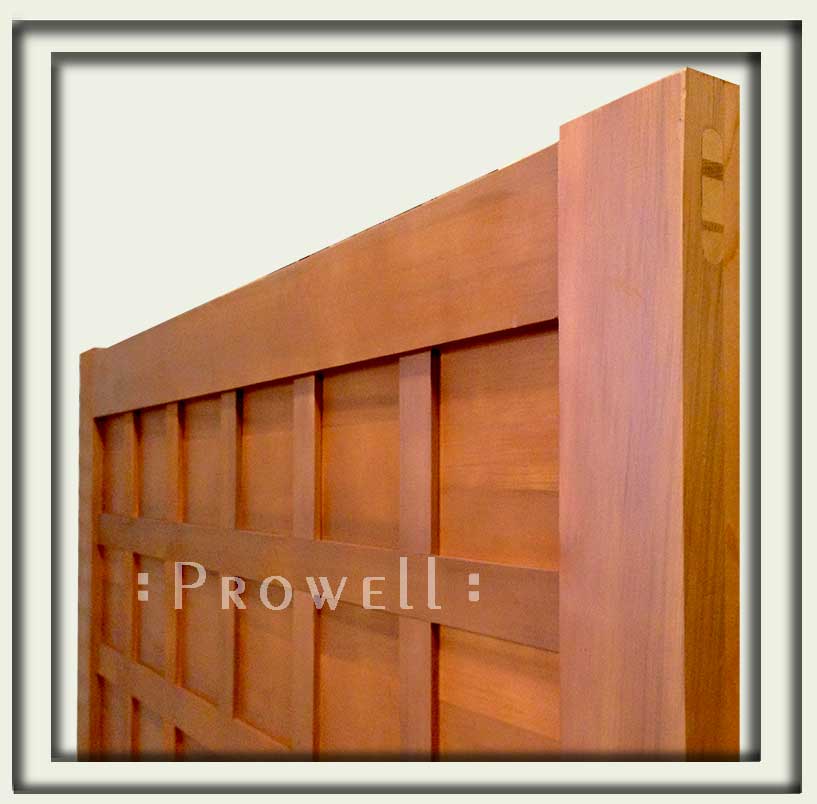

JOINERY #9

JOINERY #9

Gate style #115-2

JOINERY #9

The mortise is created on a Laguna horizontal mortiser. 1″ thick. Because each pass has a maximum depth of only 4″, and our stiles are 5-1/4″, lines are transcribed to enable to stock to be flipped end-for-end to complete the mortise from the opposite edge.

Although this same procedure can be accomplished with a simple mortise box and plunge router, the alignment is somewhat more challenging.

JOINERY #9

The 1″-thick tenon is eased with a round over bit to the same radius as the corresponding mortise.

JOINERY #9

As with our other through tenons, we create a snug fit to the mortise. Adding kerfs and expansion bores for the eventual wedges.

JOINERY #9

If you can slip a tenon into it’s mortise without resistance, then the joint is too loose. Re-cut the tenon until it’s snug enough that it requires a light tapping with your mallet.

JOINERY #9

JOINERY #9

Showing the tenon set to the mortise, extending the width of the eventual stiles, plus a little extra.

JOINERY #9

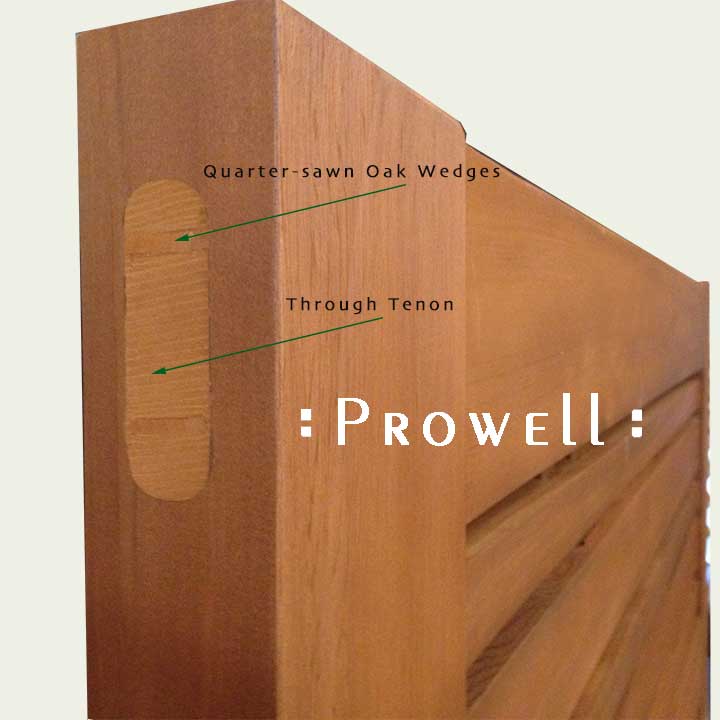

Creating the wedges out of quarter-sawn oak.

JOINERY #9

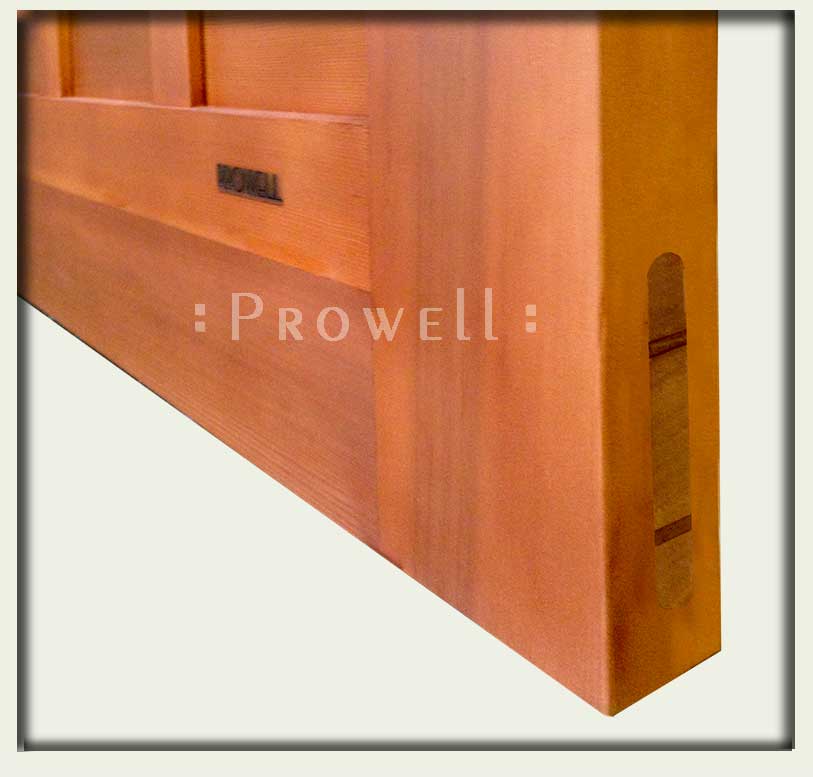

The stile dry-fitted in place. Once the glue-up process begins, the wedges are set during the same process, while the glue is still wet.

JOINERY #9

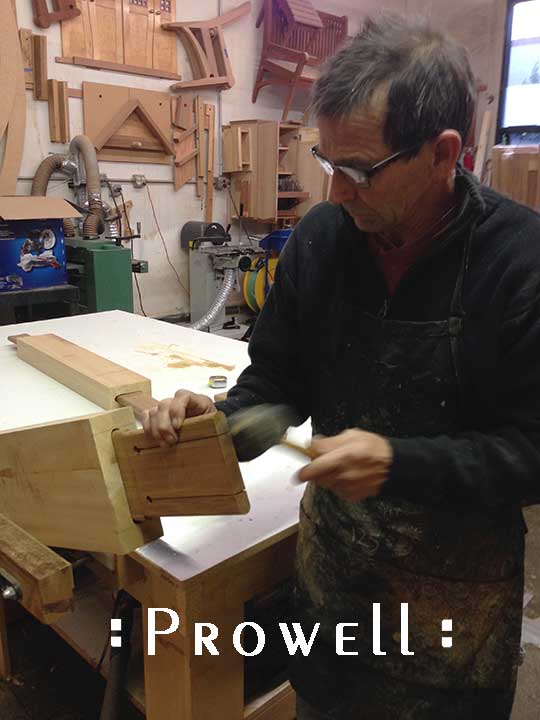

Charles setting the two wedges in place. With each tap you can feel the joint tightening, and thus strengthening.

JOINERY #9

JOINERY #9

The 5/16″ diameter oak dowel keys set in through the primary stock, and into the tenons.

JOINERY #9

Our finished product. Gate #87.

2-1/4″ thickness. 6′ ht x 6′ width.