HORIZONTAL WOOD DRIVEWAY GATES 11

Driveway Gates 11 are Base Price + 8% (As a non-biased alignment)

> Go to Base Price Table

11-1

11-1

Base Price + 8% + Option B Bias

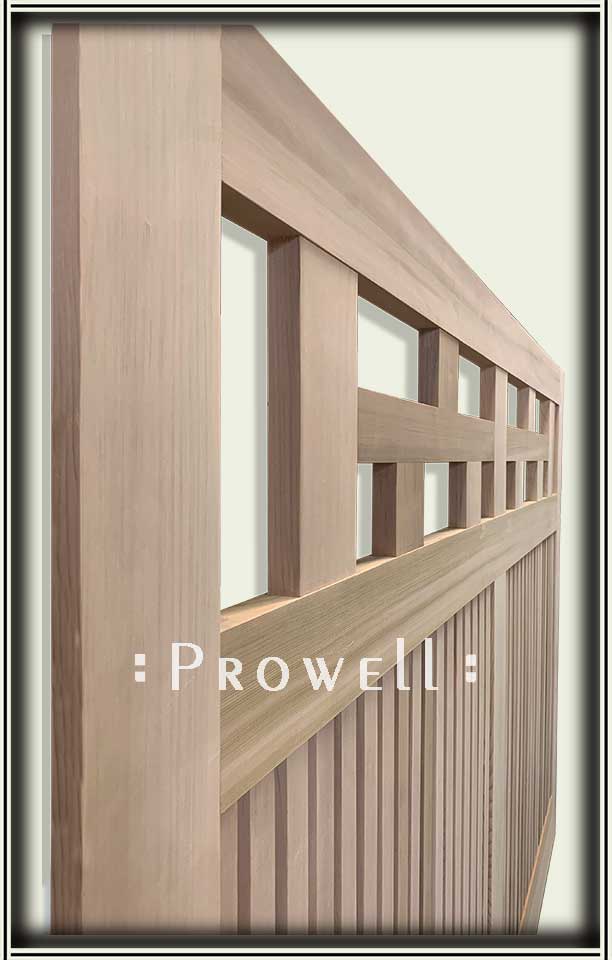

HORIZONTAL WOOD DRIVEWAY GATES 11-1

Kentfield, CA

Wooden driveway gates 11-1 built on the bias to a sloping grade that drops 8″ over 18 feet.

Narrow picket spacing of only 3/4″

See more on Sloping Grades (Option B)

DRIVEWAY GATES WOODEN 11-1

Kentfield, CA

The site features the bi-parting wood drive gates, mounted to a steel frame and automated with LiftMaster armature motors. Option B in the sloping grade options sees just the bottom horizontal rail parallel to the grade, with each picket individually cut to a tapered length. More on Sloping Grade Options

Shown with the pedestrian entry gate on the left, modified from gate style #71. The fence panels are modified from fence style 38

AUTOMATIC WOOD DRIVEWAY GATES 11-1

Kentfield, CA

The left leaf of the automated wood driveway gate 11 -1 with the entry pedestrian gate.

To mitigate the glare of traffic headlights, the lower pickets of the contemporary drive gates #11-1 are set at only 3/4″ spacing. If you stand 5º to the left or right, at a minimum of 10′ distance, there is no visibility between the pickets. A solution we’ve employed on fence panels and garden gates to the same effect.

Prowell’s Post Caps style #2

SLOPING GRADE WOOD DRIVEWAY GATES 11-1

Kentfield, CA

The Liftmaster Armature motors, provided and installed by the site automation contractor, mounted to a steel plate (in black) that is welded to the steel posts prior to wrapping the posts. The other end machine-bolts to the gate’s steel frame along the bottom rail. The steel frame was later boxed in on this project.

ENTRANCE GATES 11-1

Kentfield, CA

When the posts are wrapped, an exposed plate is mortised, as shown, that allows the adjustable hinge to weld to both the steel core post, and the steel gate frame.

Boxing in the steel frames is different from our Option #3, with the fully embedded steel frames. Here the installer builds a box, covering the steel frame only.

DRIVEWAY GATES WOODEN 11-1

Because there will be only a few of you with the sloping grades that require the above solution of a gate built on the bias, we have rendered #11-1 to illustrate the normal aesthetic .

![]()

San Anselmo, CA

The original horizontal driveway gates 11 shown with flanking Wood Fence Panels style 38–designed specifically for this gate style.

AUTOMATIC WOOD DRIVEWAY GATES 11

San Anselmo, CA

S howing the matching fence panels on the right.

![]()

IN-PROGRESS

DRIVEWAY GATES 11-1–PROGRESS

Building a wood driveway gate on the bias requires dry-fitting the layout so each picket can be scribed to a distinct length and cut on the angle determined by the math (With the length of the run, and the distance the grade slopes down or up, you can use the trigonometric function of Tan to determine the length of the hypotenuse, as well as the crucial angle to which the rails and pickets are cut in the shop. The more crucial specifications for the contemporary drive gates #11-1 were the site measurements that actually determined the rise, or slope of the grade.

11-1–PROGRESS

The wood drive gates are assembled in stages. Below the upper pattern is finished, leaving just the pre-cut multiple lower pickets to assemble . . . before the glue dries. There is no shortcut or production methodologies involved; the lower pickets are set to their tenons and glued and clamped, all before the glue dries.

11-1–PROGRESS

And once the lower pickets are set and the clamps are loosely set, Ben fine-tunes their placement to insure each picket aligns to its layout marks. At only 3/4″ spacing, any skewed picket will be readily apparent to the layman’s eye.