Electronic Access

The Ups and Downs of Electronic Access with Wood Gates

THE PRIMARY CONCERN

Prowell Woodworks does not warranty any gate for eventual repairs that are the result of a security or electronic access system that requires less than 3/8″ swing clearance.

If you’re considering a system that utilizes a standard residential lockset with a standard cylinder bolt, the swing clearance (the gap between the gate and the post) will be similar to that of the front residential entry door. A nickel’s thickness, more or less. But unlike a front residential door which is insulated on one side and further protected by jambs and headers and a roofline, the gates are fully exposed to the elements on 360 degrees to a combination of rain, sleet, snow, sunlight, heat, dew and the relative humidity of the air itself. All of this absorbed and released from the wood as a living environment, resulting in a gate width that changes and will continue to change, or breath, for the 50 years or so it adorns your property.

If you are in, say, South Carolina or Hawaii or the Caribbean, with excessive humidity and heat interspersed with afternoon rains, the gates will breath more heavily. Therefore the risks of swelling beyond a narrow ⅛” swing gap to bounce off the posts is much higher. If you are in San Francisco, with its even temperate climate, the risks are reduced simply because the gate is not reacting to excessive shifts in weather.

When a gate has only ⅛” clearance, it runs the risk of expanding to wedge against its post or jamb and require yanking and shoving to open. The repeated yanking and shoving over the course of weeks or months is not good for the joinery. The gate in many cases will continue to expand to where it simply bounces off the jamb or post. This results in the potential damage due to the wind catching it and slamming it repeatedly to bounce off the jamb or post for the duration of the wet season, which again is not good for the joinery.

The percentage of those gates with ⅛” clearance resulting in the above scenario is about 20%, which is far too high a risk if you are in the gate business. We are not willing to replace 20% of all gates we build simply to accommodate a request for ‘strike-plate actuated’ electronic access or the aesthetic preference of a standard residential lockset.

If you prefer to move forward, we will build your gate, but we will not be liable for damage due to the above issues. In other words, we will repair or replace your gate, but not for free. This is a contingent appearing several places on the web site, such as the Payment Page, as well as the statement requiring an approval sign-off.

A thorough explanation becomes complicated, and for those of you who are interested, the remainder of this page will address the issue on a more technical level.

STANDARD LOCKSETS

You’ll notice that the latch bolt below has a beveled edge. This interacts with the strike plate and as the door closes, the beveled edge of the bolt withdraws into the lock cylinder with a spring action. Once the bevel bolt reaches the center of the strike plate (the hole in the center of the plate), the spring releases and the bolt is fully engaged into the center of the strike plate. Because the bevel is on only one side of the bolt, it cannot be pushed open without turning the lock handle that withdraws the beveled latch bolt back into the lock cylinder in the door. To open the door, you must turn the lock handle.

The latch bolt is a standard diameter, simply because all doors are standard thicknesses from 1-3/8″ thick for interior doors to 1-3/4″ thick for entry doors. The diameter of the latch bolt dictates the angle of the bevel, which in turn dictates the actual length of the bevel that comes into contact with the strike plate. By the nature of this, virtually all of your interior and residential entry doors are relegated to a gap of approximately a nickel’s thickness. You might now go have a look at all the doors in your house to verify this. Bearing in mind that these doors are not gates. The residential entry door is insulated on one side and protected by a jamb and header, as well as a roofline. The interior doors are 100% insulated from the elements.

Below left is the image of a standardEmtek residential lockset with a standard latch bolt that exstends 7/16″.

Below right is an image of a standard Emtek Mortise Lock. All mortise locks, by all manufacturers, feature the latch bolt that extends 3/4″, thus allowing the necessary 3/8″ gate swing clearance.

THE SOLUTIONS:

ELECTRONIC DEAD BOLTS

–-Available through Prowell Woodworks

Because the latch bolt on all dead bolts extends 1″, the primary criteria of 3/8″ swing clearance is met.

Emtek EMPowered Dead Bolt (EMP0101)

The EMPowered lock is available as a simple electronic dead bolt where the code is entered and the bolt is withdrawn to allow access.

PRICING: $456.00

Product Code EMP0101

Oil-rubbed bronze (10B)

Satin Nickel (US15)

Flat Black (US19)

Pliched Chrome (US26)

EMPowered™ Product Features:

Standard door prep 21⁄8” bore.

Fits standard door thickness of 11⁄2” to 21⁄4”.

Complete set includes both 23⁄8” and 23⁄4” latches, strike plates and 4 AA batteries.

EMPowered Deadbolt only available with square corner latch face plate.

Tapered Deadbolt

Emtek’s standard mechanical and finish warranties along with a 1 year warranty on electronic components.

BACKLIT KEYPAD – Keypad wakes with a touch and includes numbers that won’t wear off.

OPTIONAL SETTINGS – Customized auto re-lock, privacy mode and tamper alarms with the lock settings.

MOTORIZED DEADBOLT – Quiet motor with tapered deadbolt to accommodate misaligned doors.

VOICE ASSISTANT: Will guide you through the sert-up and menu option in 3 languages.

WEATHER PROTECTED – Rubber gasket increases protection against outdoor environments.

MANAGE CODES – Create up to 25 user PIN codes to share with friends and family. Unlimited codes with Connected by August.

![]()

EMPowered ‘Smart’ Dead Bolt–EM1101

PRICING: $681.00

- Create and manage unlimited entry codes with the smart lock

- Easy to use, award-winning August mobile app

- Auto-Unlock (learn more) and DoorSense™ technology

- Works with all three voice assistants

- Compatible with leading smart home security systems and hosting platforms

- 9V battery port to prevent lockouts

- Tapered deadbolt latch to assist with latch engagement

- Easy to install, fits standard tubular door prep.

EMPowered™ SMART Dead Bolt Features:

CONTROL FROM ANYWHERE – Includes the August Connect Wi-Fi Bridge so you can lock and unlock from anywhere using your August app.

SHARE ACCESS – Grant access to your home for the people you trust. Give permanent/temporary access or set a unique access schedule.

24/7 HISTORY – See who comes and goes with smartphone notifications and a 24/7 access history in the app.

USE YOUR VOICE – Works with the three leading voice assistants; Amazon Alexa, Google Assistant and Siri.

COMES WITH AUGUST DOORSENSE™ – Know if your door is not only locked or unlocked but also closed or opened.

WORKS WITH AUGUST DOORBELLS – See who’s at your door and unlock the door right from your August app.

AUTO-LOCK – Never worry if your door is locked again. Auto-Lock can be set for immediate or on a timer for as short as 30 sec or as long as 30 min.

AUTO UN-LOCK – Auto-Unlock knows when you arrive and unlocks the door as you approach. Never fumble for keys again.

Emtek EMTouch- (E3020)

The EMTouch operates with the keypad principle, but once the code is entered, the bolt is withdrawn by physically turning the thumb piece.

PRICING: $379.00

EMTouch Product Features:

- Fits any door between 13⁄4” to 21⁄4” thick with a 21/8” bore standard door prep.

- Installs easily with only a Phillips head screwdriver.

- Easy to use installation and programming instructions included.

- Factory programmed with 2 unique, secure user codes for use right out of the box.

- Can be programmed with up to 20 user codes of your choice.

- Codes can be added and deleted.

- Easy lock operation, simply push the Emtek button and turn the exterior thumb turn to lock.

- Easy unlock operation, enter the 4 digit code and turn the exterior thumb turn.

- Programming changes can be made easily using the keypad.

- Sleek keypad has a protective coating to prevent wear patterns.

- Illuminated keypad for easy and quick operation after dark.

- Low battery indicator lets you know when it’s time to change the battery.

- Emtek’s standard mechanical and finish warranties along with a 2 year warranty on electronic components.

MAGNETIC LOCKS

— NOT available through Prowell Woodworks

No moving parts to wear out or break. No risk of swelling gates.

The series of magnetic locks are available from several manufacturers. There are several models designed for outdoor gates with the principle of allowing the gate to breath dimensionally–to expand and contract with the seasons while maintaining the magnetic hold. Magnetic locks have no moving parts to wear out or break and are virtually indestructible. 1200 Lb locks are typically used for vehicular gate applications while the 600 Lb lock is used for pedestrian gate applications.

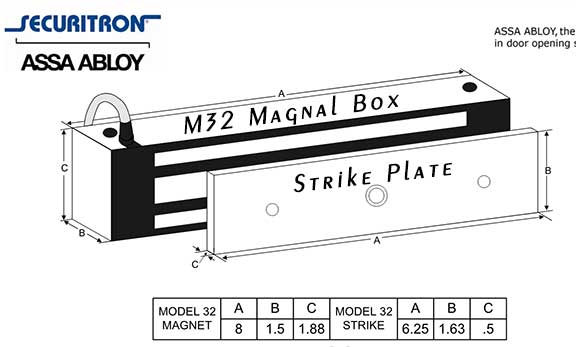

SECURITRON M32

The Securitron M32 is an electromagnetic lock with 600 pounds of holding force designed for use on access controlled interior rooms and secure areas in buildings.

The lock is weatherproof and tamper proof, to protect internal components from outside interference. An instant release circuit ensures no residual magnetism. The unit comes in an attractive brushed stainless steel finish and includes ten feet of jacketed, stranded conductor.

This magnetic lock is not recommended for protecting doors where physical assault is a possibility.

Technical Specifications:

Holding Force: 600 lbs. [272 kg]

Current Draw and Voltage: 300mA at 12VDC; 150mA at 24VDC

Operating Temperature: -40 to +140F [-40 to +60C]

Shipping Weight: 6 lbs.

Warranty: MagnaCare Lifetime Replacement Warranty

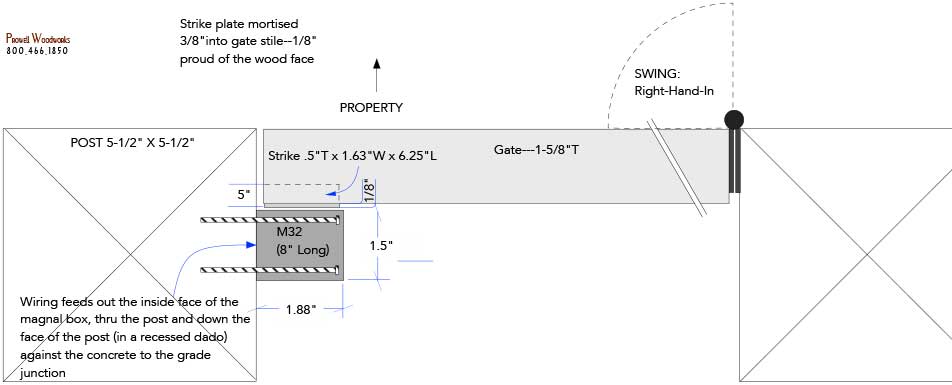

M32 box shown mounted to the inside face of the post.

M32 Strike mortised into the stile -⅛” proud of the wood face

From the street, for an In-Swing Gate.

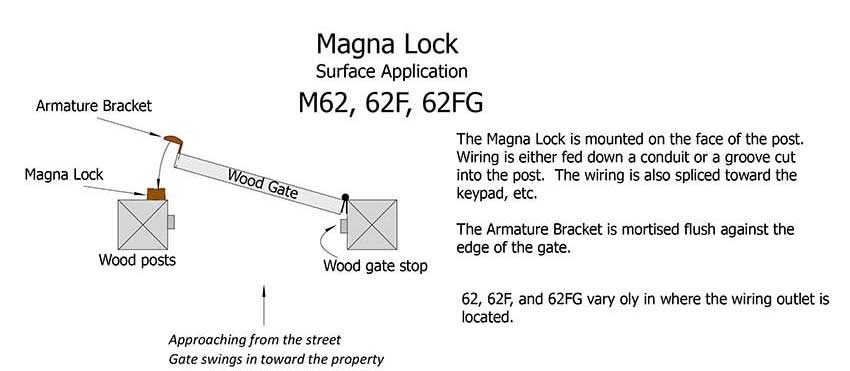

![]() Below, the Magnal M62 on double gates when you cannot mount to a post. Shown with the M62 recessed into the fixed gate with embedded wiring fed through the gate to the hinge edge and down t junction with the power source.

Below, the Magnal M62 on double gates when you cannot mount to a post. Shown with the M62 recessed into the fixed gate with embedded wiring fed through the gate to the hinge edge and down t junction with the power source.

Photographed from the property side with the gate on the right being the fixed gate and the gate on the left being the operable, opening in toward the property.The M62 requires a bracket, as shown.

The Magnal M62 application.

THE ‘STRIKEPLATE ACCUATED” ELECTRIC SECURITY ACCESS:

NOT available through Prowell Woodworks

The Accuated Strike assembly is a solution we see frequenty in the specs for large firms who’ve called out prowell for the gates. It’s an expensive, complex, semi-reliable arrangement we do not offer. But that is listed here, with approximate pricing, for those willing to hire an Electronic Access professional to manage the installation.

The system involves the following: 1) A mortise lockset/deadbolt with lever handles; 2) An electric strikeplate; 3) and a keypad actuator. 4) Gate thickness of 2-1/4″

How it Works:

- When mounted to the post or jamb, the Actuated Strike is mortised in flush and wired down the length of the post or jamb to a junction box connecting it to the power source and most commonly, a keypad release. The lockset used on the gate is a standard residential mortise style lockset, with the 3/4″ extended beveled spring-load cylinder that is set to a locked position. Upon activating the release by entering the proper code or being buzzed in from the house, the strike plate bar mounted to the post is released and the beveled cylinder can be pushed through the strike as the gate swings open.

* We do not currently offer this option, and present it here as a workable solution you, the homeowner, such that you can present it to your contractor or automation contractor. The prices are culled from the manufacturer’s retail listed pricing. We would prefer you follow this research rather than resort to an option that results in the gate you’re purchasing from us being damaged due to a system designed for residential access and not gate access. Remember: The one solid and irrefutable criteria to electric security access for a gate is that the gate has 3/8″ swing clearance.

RCI 2364-32D

All-In-One Electric Strike –

Fail Safe – Latch Entry – Brushed Stainless Steel

Approximately $289.00 +-

The beveled latch bolt collapses over the rear wall of the strike plate and into the cavity. Upon entry, with the lockset in a locked position and the handle unable to turn, the non-beveled edge of the bolt passes through only when the rear wall is electronically engaged and released.

The strike plate is best wired when using a pair of jambs. The wiring is fed to the back of the jamb and down a groove to stub out at the ground. From the ground, the site electrician can either split the feed for one set of wires to a keypad on the post adjacent to the lockset, while also wiring a feed to the house for a push-button release.

#3545 “Mormot”

Emtek Mortise Lockset/dead bolt “

Stainless Steel.

Approximately $533.00 +-

Latchbolt operated by lever from either side, except when outside is locked by stop-button or projected deadbolt. Deadbolt operated by key outside or turn inside. Key outside operates both bolts. Latch deadlocked by auxiliary latch or deadbolt. Inside lever retracts latchbolt and deadbolt simultaneously.

Doorking 1515-080 Smart Open Stand-Alone

Keypad – Compact Surface Mount

Approximately $370+-

PROPERTIES

- Use cell phone or keypad for entry

- Compact Surface Mount

- Stores up to 400 codes, 4 or 5 digit

- Program from the keypad or from an Android Smartphone with the DKS Manager App

- Wrong code lockout settable from 3-9 tries and 1-9 minutes

- Low power mode for solar applications

- Single Form C dry contact relay

- Operates on 12 to 24 volt AC or DC power

- 2 year limited warranty

- All Products Require a 3-5 Day Lead Time

The DKS Smart Open app allows users to access their model 1515 controlled entry point with their Android smart phone or they can enter their personal code on the 1515 keypad. The Digital Lock Manager app allows managers to program entry codes, hold open codes, etc. directly from their Android phone.

SMART OPEN

This smartphone application allows you to use the NFC feature to automatically enter your digital access code in a DKS Model 1515 digital lock. No more entering 4 or 5 digit codes on a keypad! Just open the DKS Smart Open application and hold your phone near the DKS logo on the lock. The digital lock will automatically recognize your valid entry code and unlock the door for you!

DIGITAL LOCK MANAGER

This application allows you to manage the access codes in DoorKing’s model 1515 digital entry lock using the Near Field Communication (NFC) feature on your Android phone. You can easily add and delete access codes, set the relay strike time, add Hold Open Codes, set lock-out times and more!

Go to DoorKing Model 1515 Digital Lock – Smart Open to download applications.

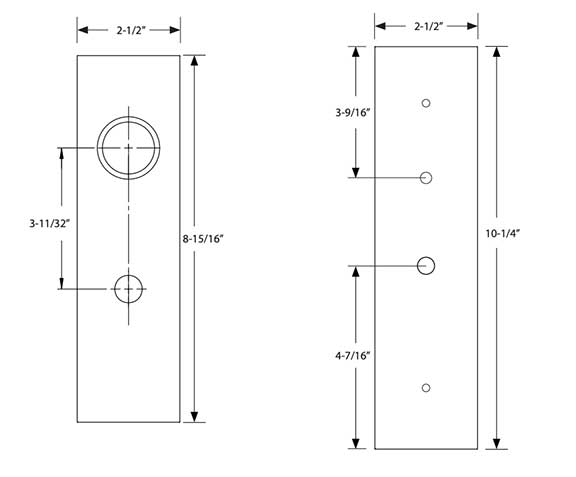

‘#3435 Mormont’ Specifications

THE ‘SIMPLEX CYLINDER BOLT AND THE HES 5200 ELECTRIC STRIKE:

NOT available through Prowell Woodworks

Simplex Bolt

The Simplex bolt is considerably easier and less expensive to buy and install than the full mortise locks, while it achieves the same result of a beveled spring bolt that extends 3/4″.

There is no handle or grip. This you source separately, not as an operable latch but a simple grip or knob.

$56 +/_ Available thru Zorro

- Mfr #: 20114426D01

HES 5200 Strike

Stainless steel w/bronze patinas.

$125 +/_ depending on the source

Horizontal Adjustability

- Easily adjusts once installed to accommodate for the position of the latchbolt

- Simple installation process

Versatile Design

- Field selectable fail secure/fail safe

- Accommodates latchbolts up to 3/4″ throw

- Plug-in connector and trim enhancer included

Tested for Durability

- ANSI/BHMA A156.31, Grade 1

- Static strength 1,500 lbs, Dynamic strength

The principles of a flush-joined wood gate.

Wood comes to us from the forests of British Columbia, spec’d for a minimum number of growth rings that insures the harvest is fully matured. We cannot buy wood from the American northwest simply because it is harvested far too early. From BC, the logs are shipped to the mill of our choice in Washington state, and from the mill they are shipped to our shop in northern California as dimensioned lumber that is clear, vertical-grained, and kiln-dried to about 7% moisture. All three regions–BC, Washington, and N. California–share more or less a similar climate. Lots of rain, temperate humidity, and mild summers.

Once it leaves the shop, as an assembled product, and embarks on what’s often a cross-country transit to a climate wholly different from its genetic DNA over the past several millennium, it experiences for the first time, once installed, the full 360-degree exposure to a climate of severe winters, or humid summers where the air is thick as Jello.

The result, for several weeks, is the wood breathing heavily. The way someone from San Francisco might do if visiting Mississippi in August. The wood acclimates and adjusts, gasping and panting in a sequence of expansion and contraction that goes on for several weeks until eventually stabilizing and settling into a pattern of minimal breathing that will last for the next several decades.

It’s those first several weeks that present a problem for all those preferring an electronic access for their gates.

**

Wood breathes perpendicular to the grain. As it takes on rain or dew or humidity, it swells. As it experiences dry heat, it shrinks. The two vertical frame pieces of the gate are called Stiles. These breath horizontally. So if they arrive at 5-1/4″ width, they will, depending on the regional climate, potentially expand to 5-3/4″ width. But because they arrive at only 7% moisture, they will seldom contract, or shrink, more than 1/4″.

Why is kiln-dried 7% moisture preferred? If we worked with green wet wood that had been logged the week before and was still wet with the plasma of living cells, our tight joints would open up as the wood dried and shrank the way firewood must dry before being burned. For assemblies relying on woodworking joinery instead of fasteners, it is essential that the joints are cut and fashioned with a relative moisture between 7-9%. (less than this and the cell structure of the wood fiber itself breaks down, hence why you see very little in the way of exposed wood assemblies in places like Phoenix or Las Vegas).

**

Now that we understand the properties of the wood, let’s consider the variables of where it goes once leaving the shop in northern California. If the gate is delivered to somewhere within the San Francisco Bay Area, there will be minimal acclimation, as the entire Bay Area shares a similar temperate climate. If a gate is shipped to Memphis, or basically anywhere with seasons and relative humidity, it takes on the moisture of that humidity and swells, or expands to a larger width (Remember, the Stiles are what swell and they swell horizontally). If we finish a gate in, say, January, and ship it east, the dimensional change is minimal simply because cold and snow tend to contract the wood. If we build a gate in July and ship it east into the high humidity of summer climate, the gate swells. The more heat and humidity at the end destination, the more initial swelling. And because just about everywhere east of the Pacific coastal range experiences normal winters and summers with rain and humidity, this phenomenon is exempt only within those areas along the Pacific coast. A narrow corridor where the weather is unlike anywhere else in the country. (A good reason why it is also an area of high housing costs).

**

The properties of a typical electronic locking system only engage with a swing clearance (the gap between the gate and the post) of 1/4″ or less. Imagine your front door, or any door within your house. Look at the gap between the edge of the door on the lock side, and the jamb and you will see the approximate thickness of a nickel. That’s because the same type of lockset is most often used on gates with electronic releases. And because the nature of the cylinder set within the edge of the gate, or door, has a spring-loaded beveled edge that engages the strike plate, the 1/4″ gap cannot be more or the bevel will simply not engage at all. If that cylinder were longer, and the gate swelled, it would be the shaft of the cylinder itself, and not the bevel, that bounces off the strike plate. So the nature of standard lock-sets do not work, by physical design, with a swing gap of anything more than 1/4″.

But 1/4″ is too little to accommodate the acclimating expansion of our gates. The gates, upon arriving and being installed and absorbing the changes in varying climate regions once fully exposed, naturally begin to swell once they experience their first season with humidity. (So if the gate is installed between late October and early March, everything will be fine until the heat and summer rains and daily humidity of the warmer season arrives).

The gate swells and quickly it swells beyond the 1/4″ gap of your electronic lockset and it continues to swell until it becomes wedged tight against your gate post. The electronic lock is instantly disabled and at this juncture the gate must be shoved and pushed and yanked simply to gain access. A horrible set of parameters for the gate. And because the gate will not latch or close, it often is left to slam and bang against the post with each thrust of wind. And eventually something gives. First your patience followed by a temper tantrum followed by a string of cursing expletives directed toward Prowell Woodworks. Followed by the gate finally giving in to the abuse and manhandling and our homeowners calling demanding a new replacement gate.

The above scenario occurs about 20% of the time with any gate shipped anywhere with a swing clearance of anything less than the preferred 3/8″ swing gap.

So you will see others with electronic access system that seem to work just fine. Perhaps even your neighbor’s gate. But if you are in the gate building business, a 20% recall rate is about 19.999% higher than what is acceptable.

Therefore, any gate subsequently utilizing a standard door lock or electronic access loses it’s warranty the moment it leaves our shop. We will not replace such a gate. There is no way to hide the evidence of such a lockset. You gambled, and the price for those whose imperatives are electronic security, the next option is wrought iron, preceded by a round of cursing expletives directed toward Prowell Woodworks.