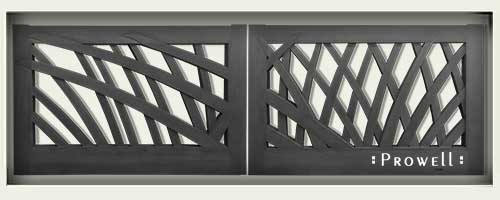

CUSTOM WOOD DRIVEWAY GATES 220

Wood Driveway Gates 220 are Base Price + 75%

> Go to Base Price Table

The modern elements of joinery and woodcarving

220

220

Base Price + 75%

WOOD DRIVEWAY GATES 220

Kauai, Hawaii (Noho Kai Gated Community)

Prowell’s hand-carved entrance gates 220, designed as identical entry and exit gates to a gated community.

CUSTOM DRIVEWAY GATES WOODEN 220

Kauai, Hawaii

13′ 4″ overall width x 53″ height. Featuring invisibly embedded stainless steel frames.

Photo credits: Elisia Lisa Press

Photo credits: Elisia Lisa Press

DUAL DRIVE GATES 220

Kauai, Hawaii

Showing the entry and egress gates, flanked by the stone columns with lighted insert panels.  Photo credits: Elisia Lisa Press

Photo credits: Elisia Lisa Press

DRIVEWAY GATE DESIGN 220

Kauai, Hawaii

The column inserts are lighted and fitted with blue glass backing.

Photo credits: Elisia Lisa Press

CUSTOM WOOD DRIVEWAY GATE 220

Kauai, Hawaii

Showing the continuation carving. The primary reeds are 3″ thick, several of which have continuation carvings at the tips. The secondary reeds are only 2-¼” thick.

Photo credits: Ben Prowell 2018

Photo credits: Ben Prowell 2018

CUSTOM WOOD CARVED GATES 220

Think Hawaii. The natural grasses and lush foliage of reeds and tropical palms and the solution, naturally, was the design that resulted in the 220.

Photo Credits: © Ben Prowell 2018

Photo Credits: © Ben Prowell 2018

DRIVE GATE 220

Two of the four accompanying column insets, backed by blue art glass and LED lighted flat panels. Some day, we’ll hopefully receive evening photos that show these panels when lighted.

Photo Credits: © Ben Prowell 2018

Photo Credits: © Ben Prowell 2018

GATE 220–IN PROGRESS

Photo Credits: © Ben Prowell 2018

Know the fundamentals of joinery by the time you’re twenty. Expand on them throughout that decade and when you’re thirty, Ben’s age in this photo, you have a repertoire of innovations–personal discoveries. At your disposal and all of them clamoring to be brought off the bench, to be called upon for those pieces of work where the fundamentals are just not good enough.

220–IN PROGRESS

Photo Credits: © Ben Prowell 2018

Ben contemplating the next step.

220–IN PROGRESS

Photo Credits: © Ben Prowell 2018

The embedded steel frame seated in it’s dado, with the mirrored half ready to laminate over the frame for the full 3″ thickness. Showing the hingeplates, to which the hinges will ultimately be welded on site.

220–IN PROGRESS

Photo Credits: © Ben Prowell 2018

For the sake of economy, there were only three templates to create the various arcs. Their settings within the general design was a matter of rotating each piece to its final placement.

220–IN PROGRESS

Photo Credits: © Ben Prowell 2018

Creating the shadowlines with chisels and drawknives.

220–IN PROGRESS

Photo Credits: © Ben Prowell 2018

Carving the continuation reliefs.

220–IN PROGRESS

Photo Credits: © Ben Prowell 2018

The completed patterns themselves are assembled and set into the embedded frame as inserts.

220–IN PROGRESS

Photo Credits: © Ben Prowell 2018

Scribing a fit. When finish carpenters install a cabinet to a wavy wall, they’ll use a compass to mirror the contours of the wall onto the cabinet trim. Another means is a scribing board, shown below. One edge holds a pencil lead seated into a cove and taped such that it is perfectly aligned to the edge of the chamfered board.

220–IN PROGRESS

Photo Credits: © Ben Prowell 2018

A typical column insert flanking the gates.

>>>BACK TO PROWELL HOME

The Designs of Prowell Woodworks are protected by Patents and Patents Pending.