GARDEN GATES 200A

Santa Barbara, CA

Although the Entry Gates 200A and 200 are clearly related, the original #200 settled in the arid desert east of Los Angeles, the #200A was modified to its setting overlooking the bluest Pacific Ocean in Santa Barbara.

GARDEN GATES 200A

Santa Barbara, CA

Wooden wood gate 200A is a collaborative effort with the site architect Carl Schneider.

A good example of how nearly all of the 140 +_ original designs on our gate galleries were originally the result of either speculative designs or modifying a given gate style to the existing precedent of the site’s aesthetics, or something created from nothing.

The lines to the 200a wooden garden gate design were influenced by not only it’s portal gateway to the Pacific, but to the iconic architecture of the house itself (see below)

Translucent acrylic rod, diffusing as the setting sun angles across the gate.

Upper opaque Plexiglas for a modicum of eye-level privacy.

Carl Schneider, AIA, NCARB

CSA Architects

805-962-4575

cschneider@csa-arch.com

photo credit: © ben prowell 2022

photo credit: © ben prowell 2022

GARDEN GATES 200A

Santa Barbara, CA

The upper section of the backyard gate is fitted with white opaque polycarbonate, as per the homeowner’s request.

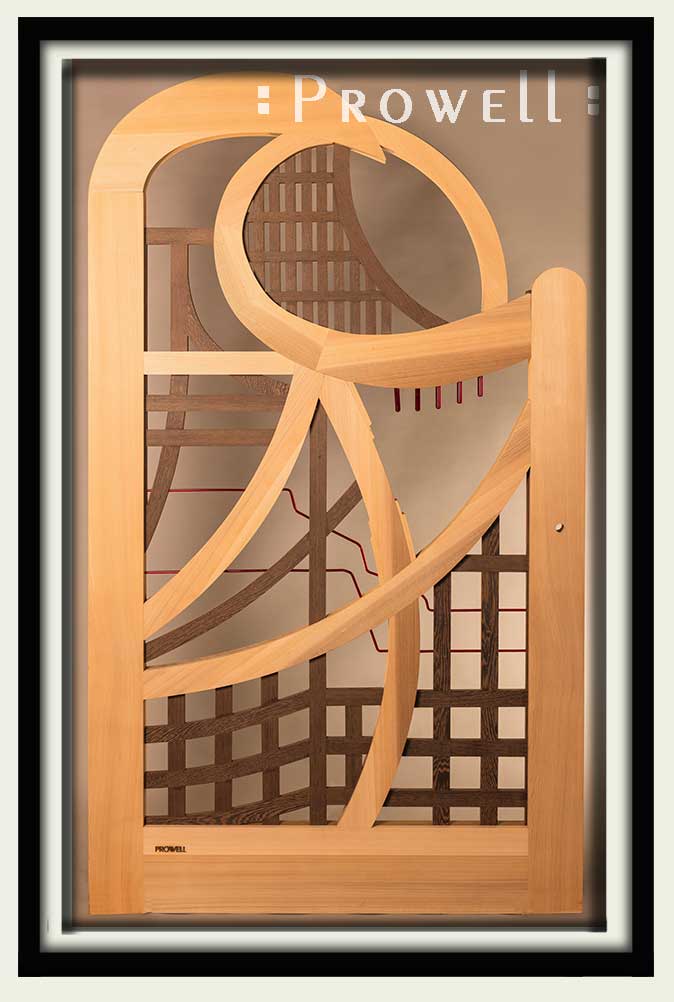

GARDEN GATES WOODEN 200A

Santa Barbara, CA

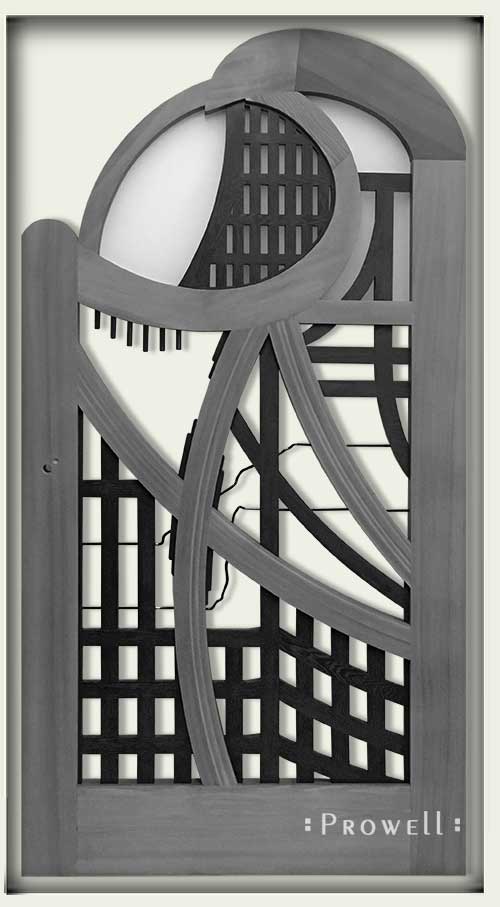

Garden gate design 200A, exposed and unencumbered.

CUSTOM WOOD GARDEN GATE 200A

Santa Barbara, CA

photo credit: © ben prowell 2022

photo credit: © ben prowell 2022

WOOD GATE 200A

Santa Barbara, CA

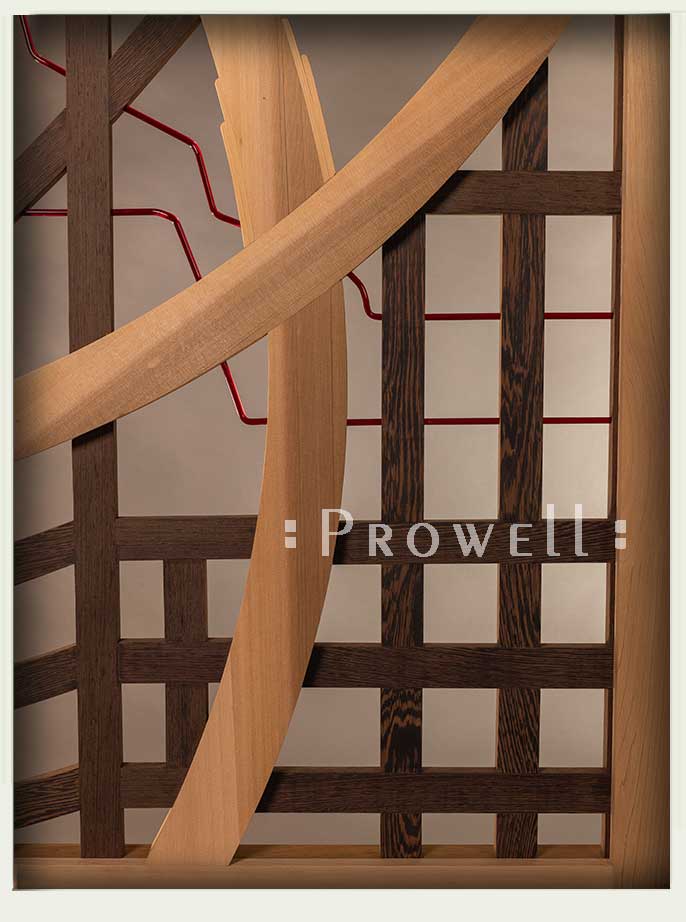

The meandering dark red acrylic rod, as a signature of the gate design 200 and 200a.

photo credit: © ben prowell 2022

photo credit: © ben prowell 2022

![]()

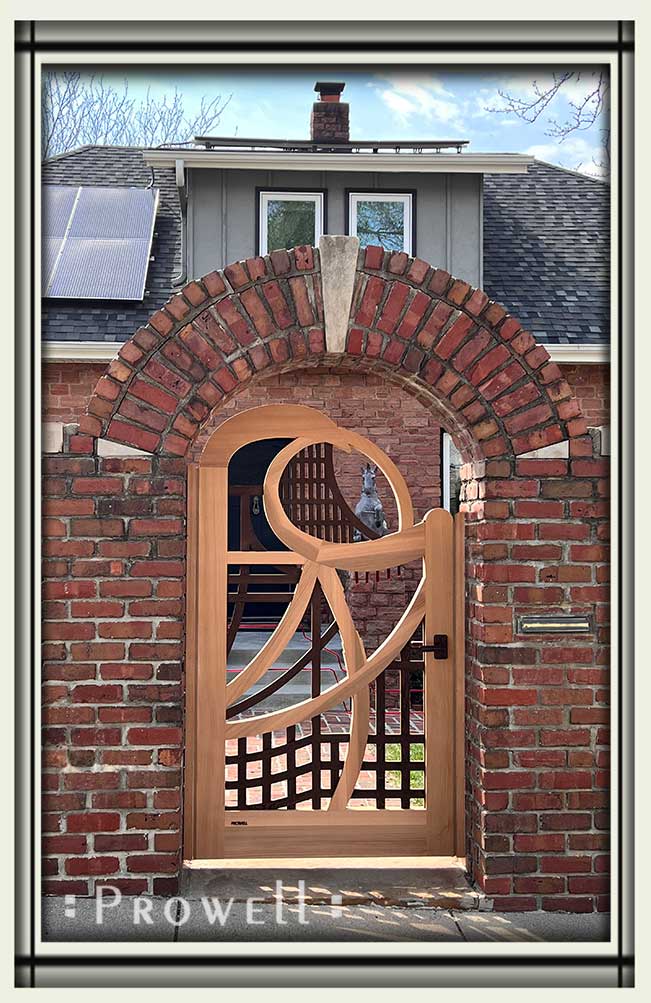

WOODEN GARDEN GATE DESIGNS FOR THE MAIN GATE–200-A1

Garden Gate 200-A1 is Base Price + 365%

Go to Base Price Table

Omaha, Nebraska

Custom wood main gate 200a-1 eliminates the upper opaque plexiglas.

photo credit: © ben prowell 2022

photo credit: © ben prowell 2022

MAIN GATE 200-A1

Omaha, Nebraska

Wooden garden gate 200a-1 conforming to the brick arch. Brick arches are a classic example of form-following-function, with the earliest examples dating to the ruins of Babylonia in 1400 BC. Each brick relies on the adjacent brick for a structural stability that can ultimately withstand the stress load of some of the most renown bridges on the globe. Here, however, it simply allows a new gate to liven up the entry of an aging invitation.

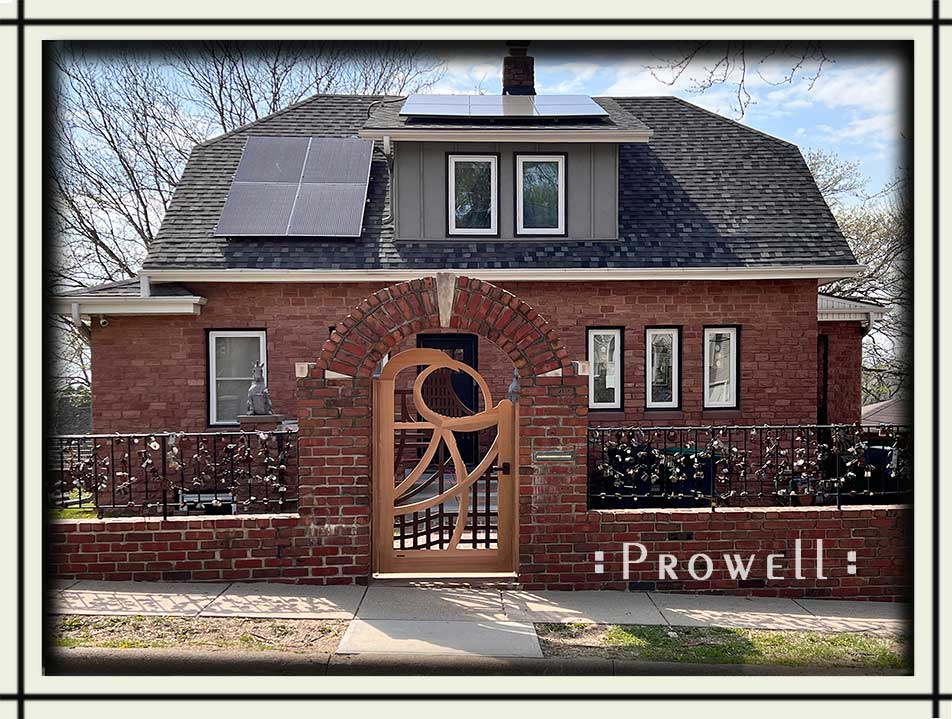

GARDEN GATE 200-A1

Omaha, Nebraska

A look at the stone cottage, built in 1936, and never occupied. Sitting empty for 87 years . . . until our patron arrives with a complete renovation of the interior. The gate itself throws a dollop of whimsy in the mix, while not so disparate as it might seem at first glance. Over the years, decades, people have taken to adorning the railing with padlocks. Hundreds of padlocks.

The legend goes, regarding this phenomenon, that a woman who had lost her lover during World War I started fixing padlocks on Hungarian bridges where they used to meet. It was her way of expressing that her love was unbreakable. Soon, the trend caught on and became a tradition not only in Hungary but also in other parts of the world. Including Omaha, Nebraska.

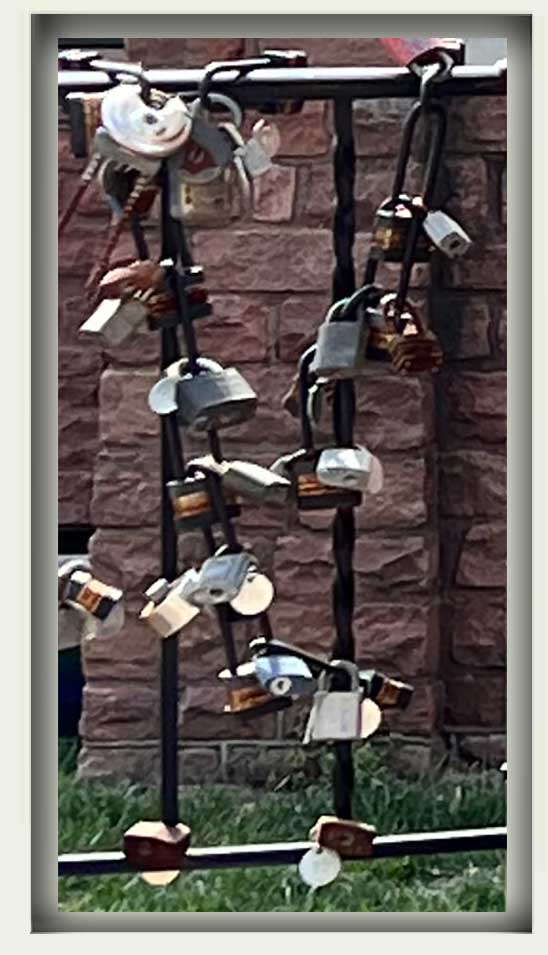

WOOD WALKWAY GATE 200-A1

Omaha, Nebraska

Interesting how there are no keys. The locks therefore cannot be opened, and the love not broken?

GARDEN GATES in WOOD 200-A1

Omaha, Nebraska

A look at the meandering acrylic rods.

photo credit: © ben prowell 2022

photo credit: © ben prowell 2022

WOODEN GARDEN GATE 200-A1

Omaha, Nebraska

The lower left wenge grid.

photo credit: © ben prowell 2022

photo credit: © ben prowell 2022

WALKWAY WOOD GATE 200-A1

photo credit: © ben prowell 2022

photo credit: © ben prowell 2022

![]()

IN-PROGRESS

GARDEN GATE 200a-1 —PROGRESS

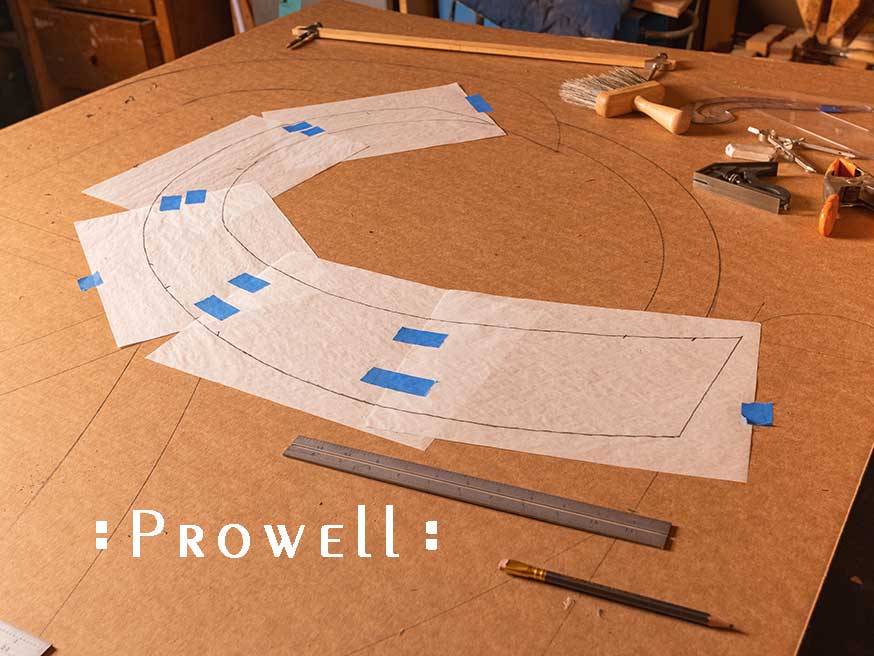

The layout of the primary components of the gate on cardboard, first, and then a tracing template of the various arches.

Photo credit: Ben Prowell

Photo credit: Ben Prowell

ENTRY WOOD GATE #200A-1 PROGRESS

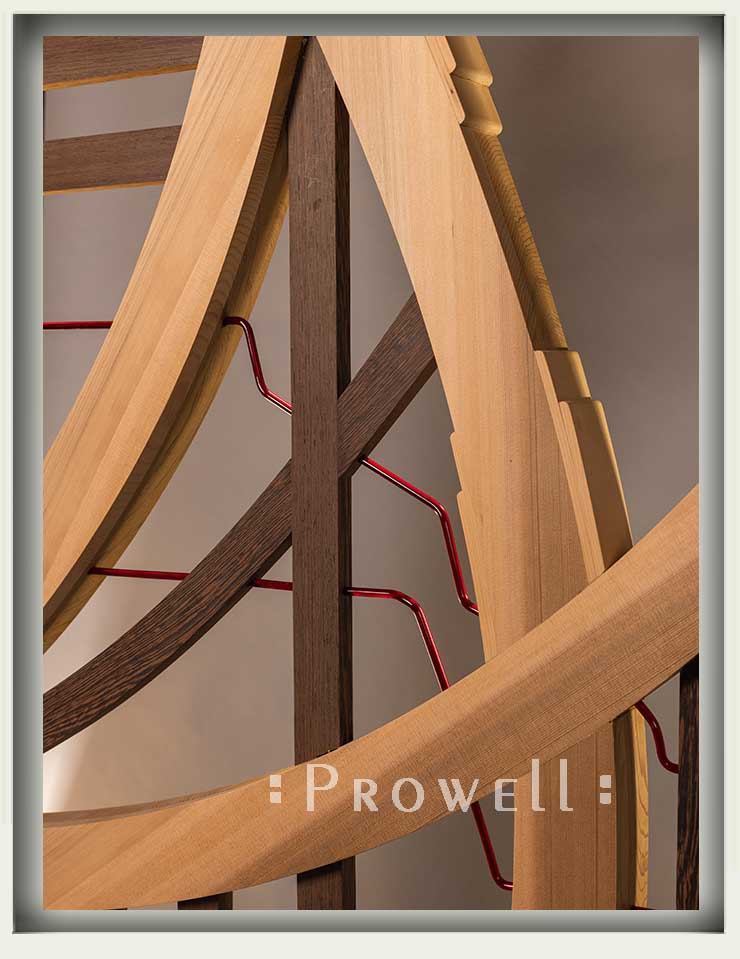

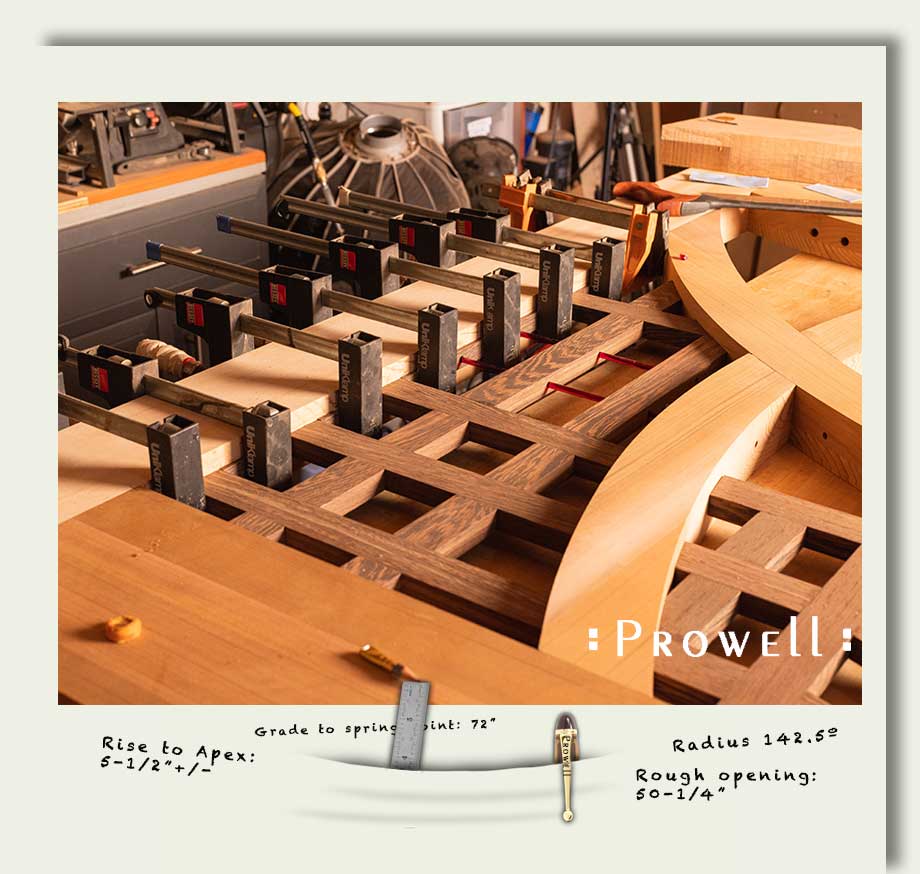

The rough, glued-up top grid assembly.

Photo credit: © Ben Prowell 2022

Photo credit: © Ben Prowell 2022

200a-1 –PROGRESS

With the stiles and rails and the various arches created, they are scribed to fit and then taped to help insure they don’t budge or shift. At this stage, they are not mortised in place, just dry -fitted.

Photo credit: © Ben Prowell 2022

Photo credit: © Ben Prowell 2022

200a-1 –PROGRESS

The top wenge grid shown fitted within the top ‘wave’ arch. Each of the wenge grid dividers will be mortised to the thicker arch.

photo credit: © ben prowell 2022

photo credit: © ben prowell 2022

200a-1 –PROGRESS

Everything still loosely fitted.

photo credit: © ben prowell 2022

photo credit: © ben prowell 2022

200a-1 –PROGRESS

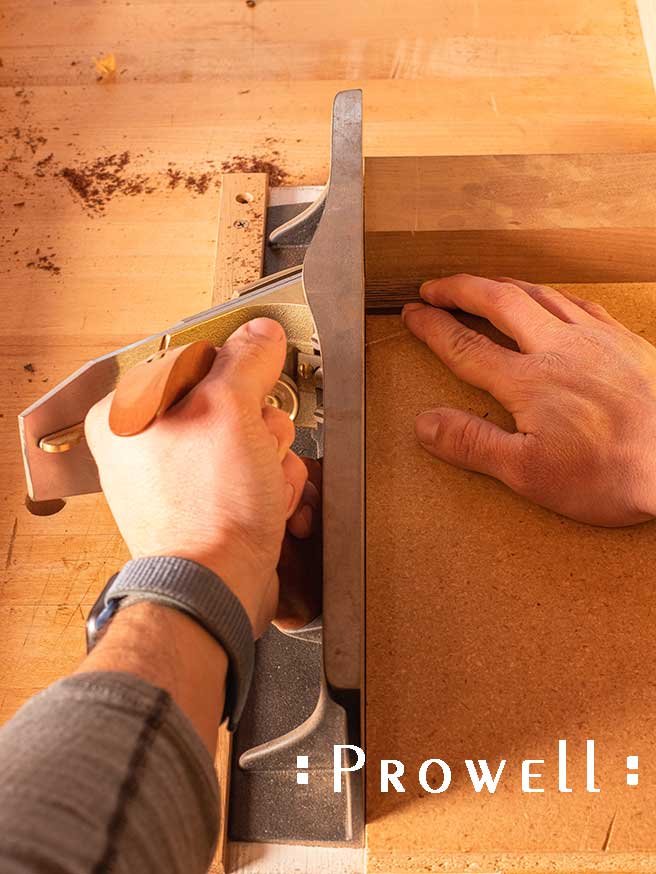

Piecing together the bottom-left grid assembly. For now, a dry fit. Ultimately each piece will be mortised to another.

photo credit: © ben prowell 2022

photo credit: © ben prowell 2022

200a-1 –PROGRESS

The Shooting Plane, with it’s dedicated jig, fine-tunes the length of this small piece of wenge by planing the end grain in lieu of the more cumbersome cross-cut.

photo credit: © ben prowell 2022

photo credit: © ben prowell 2022

200a-1 –PROGRESS

Continuing on with the bottom-right grid, and the center wenge splines.

photo credit: © ben prowell 2022

photo credit: © ben prowell 2022

200a-1 –PROGRESS

The boring template to insure the multiple acrylic rods, or organ-pipes, are plumb to a changing arc

photo credit: © ben prowell 2022

photo credit: © ben prowell 2022

200A– PROGRESS

The below photos are from the original #200A, commissioned in 2017.

In creating the various radius arcs for the secondary wenge components within the abstract garden gate designs of #200-A, Ben turns to an ancient method of a pliable 1/4″ thick stock, tensioned with a string coupled with a turnbuckle that allows for slight adjustments to the radius. With this he can then trace the eventual arch of each components onto the wenge stock.

200-A –PROGRESS

Because so many of the intersecting lines are unique, they are created one piece at a time. No multiples.

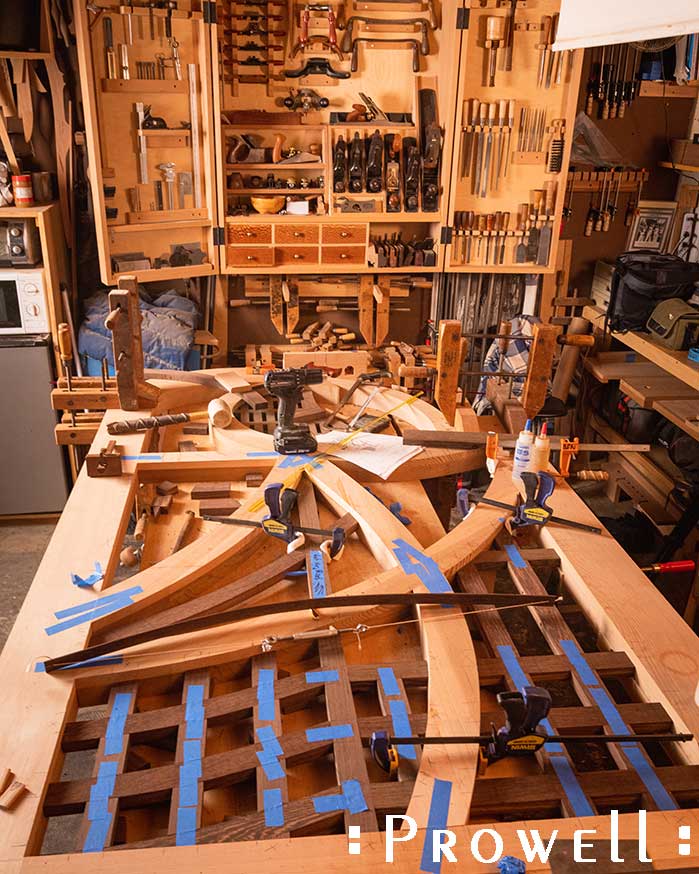

200a– PROGRESS

A confusion of awkward clamp settings. Fabricating each single component individually is only the first step. What follows is creating the joinery, and then clamping into place such that the clamps themselves do not tweak the original dry-fit.

200a– PROGRESS

200a– PROGRESS

200a– PROGRESS

The acrylic rod is purposefully bent and twisted with the careful use of a heat gun. Once it’s in place, wax paper and blue tape is applied to protect it from being scratched or blemished, as well as the overspray from the finishing process. It’s important that the rod be unblemished, as it eventually becomes a refracting rod once exposed to the sunlight.

200a– PROGRESS

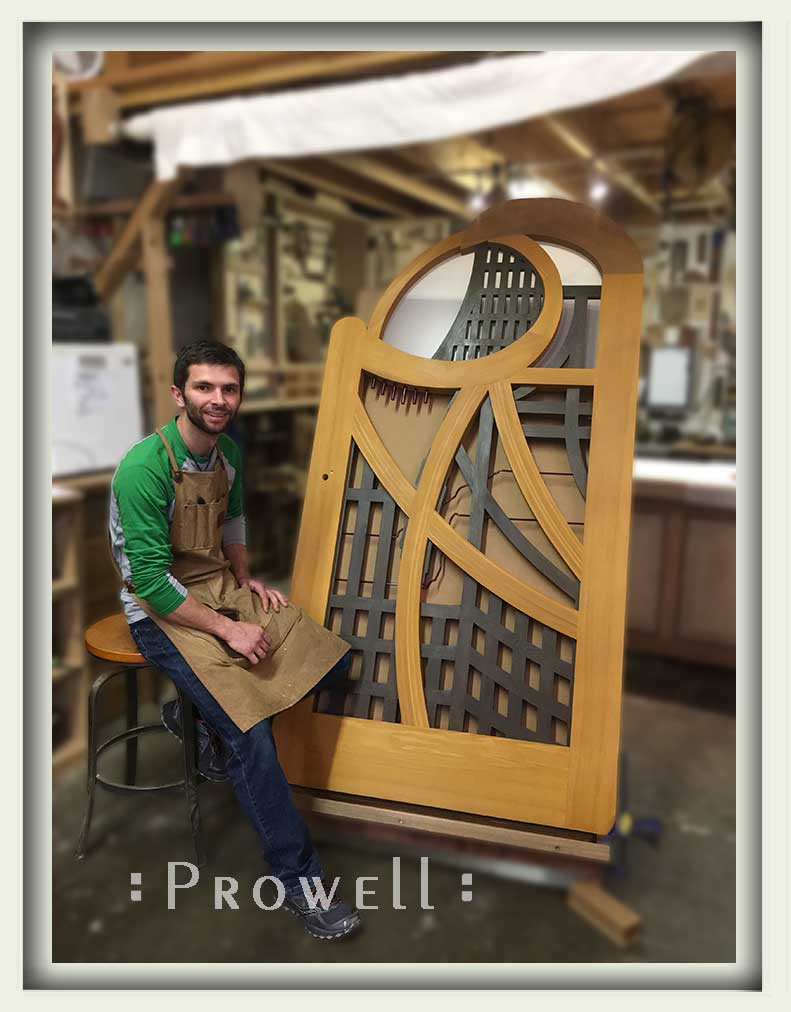

Ben Prowell with the completed abstract garden gate designs #200-A. The end of an absorbing commission and ready for the craters.

200a– PROGRESS