ARCHING WOOD DRIVEWAY GATES 14

Driveway Gates 14 are Base Price + 13% – 18%

> Go to Base Price Table

AUTOMATIC ARCHING WOOD DRIVE GATES 14-4

Lookout Point, NY

(Lower open slots)

Wooden arching gates 14-4 at 2-1/4″ thickness. Single lower floating panels with open slots.

AUTOMATIC ARCHING WOOD DRIVE GATES 14-4

Lookout Point, NY

Wooden driveway gates 14-4 have an overall opening width of 11′ 8″ between existing stone columns x 72″ to the apex. Mounted to jambs tucked to the underside of the column caps.

Because the stone is irregular, the jambs are embedded, mounting against the block core and the stone cut to fit the jambs.

![]()

DRIVEWAY SECURITY WOOD GATES 14

Kent Woodlands, CA

Lower vertical stiles and lower open slots

The two vertical mid-stiles of the privacy wood driveway gates 14 are to accept the motor arm of a stationary pad-mounted style motor. These mid-stiles are placed such that they accommodate whatever motor style is being used by the site contractor. This is necessary only for overall openings greater than 12′.

WOOD PRIVACY DRIVE GATES 14

Kent Woodlands, CA

Wooden privcy driveway gates 14 in Marin County, CA as an assembly, flanked by a pedestrian Gate Style #5 on the right and a stationary Wood Fence Panel Style #1 on the left, separated by four Prowell Lighted Columns Style #3.

DRIVEWAY SECURITY WOOD GATES 14

Kent Woodlands, CA

For the accompanying pedestrian gate, the homeowners have insisted upon utilizing a Rofu-style electronic lock-set. A convenient solution to provide security when the house itself is not visible to approaching visitors. And yet Prowell does not generally support electronic access simply because the lock-set required mandates a close swing clearance, such as the lockset of a front residential door. But a gate is exposed to the elements and a front door is insulated on one side and covered by a jamb and roof. The gate will swell and contract with the seasons, and there is a 30 percent probability those lock-sets configured with an electronic access will not close in the wetter seasons.

More on Electronic Access.

![]()

14-2

14-2

Base Price + 15%

AUTOMATED WOOD DRIVEWAY GATES 14-2

Essex, Connecticut

(Lower center vertical stile, no lower open slots)

As a handsome looking entry in rural Connecticut where we have double off-set wood driveway gates where the smaller gate is available for pedestrian use. This configuration can also be seen with Driveway Gate style #2-4

*Showing the added upper center vertical stile separating the blue-stain pickets.

DOUBLE OFF-SET WOOD DRIVE GATES 14-2

Essex, Connecticut

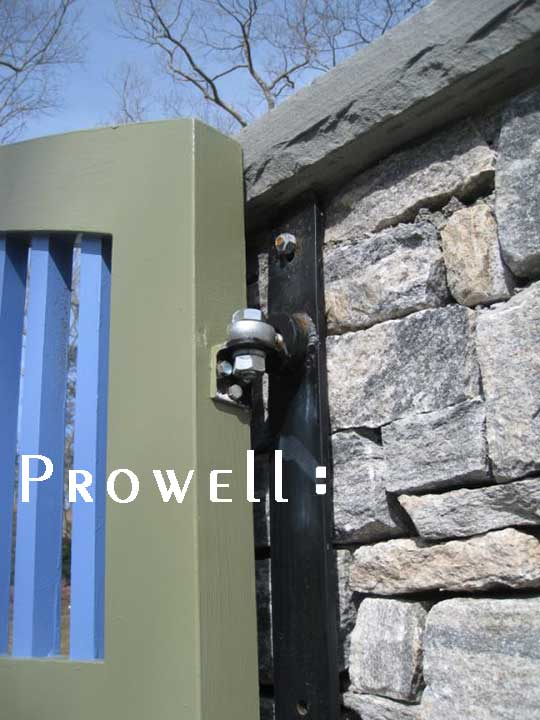

Here the contractor has elected to mount a steel plate to the columns using a threaded rod embedded all the way to the block core. He then welds his pivot style hinges to the steel and bolts the other end to the wood gate. (See Specifications).

![]()

DRIVEWAY GATES WOODEN 14-3

Menlo Park, CA

(Lower center vertical stile. Lower open slots)

Arching wood driveway gates 14-3 in Silicone Valley, CA, mounted to steel 6×6 posts. Shown with Fence Style #1. It’s also an opportunity to illustrate the effect of a simple brick threshold border that parallels the gateway.

WOOD ARCHING DRIVE GATES 14-3

Menlo Park, CA

Although commonly the drive gates would extend off the corner of the house, here we see how the adjoining panels bring the wood entry gates out another 12′, increasing the enclosed area while adhering to the local codes of a 12′ setback from the sidewalk.

![]()

WOOD DRIVEWAY ENTRANCE GATES 14-1

Novato, CA

(No lower center vertical stile. Lower open slots.)

The original Driveway Gate 14 from the mid-1990’s in Hamilton Field, Marin County. Shown with a softer arch. The overall opening is less than 12′ and does not require a steel frame.

Hamilton Field was, for many decades, a significant military air field. Like so many bases in California, it closed in the last 1970’s and was opened to general housing. A little history, for those who are interested

![]()

ENTRANCEENTRANCE WOOD GATE 14-5

Petaluma, CA

(Lower center vertical stile. No lower open slots.)

Manual. 115″ overall width. No steel frames required for overall openings of 12′ or less.

Show with Rocky Mountain latch E414

![]()

14-6 IN-PROGRESS

Creating the arched top rail for double driveway gates is easily accomplished with the help of having fabricated multiple templates to accommodate various rough opening widths.

Without the template and the gates must be laid out, as shown, but followed by scribing the arc with a radius point that’s often 12′ away!

Photo credit: Ben Prowell

Photo credit: Ben Prowell

14-4—-PROGRESS

Planing the softly arching underside of the top rail. Once the arc has been scribed with a radius stick, and roughed out on the bandsaw, the edge is tuned to create a consistent, smooth arc using the circular compass plane.

Set the plane onto the underside of the arch and adjust the top gear to where the sole is a little more acute than the radius of the wood arch. It essentially does the same job as the spokeshave, but better. Both tools rely more on the woodworker’s feel than a need for good eyesight.

14-4—-PROGRESS

Stanley Victor #20 Cast Iron Circular Compass Plane. Circa 1879.

Photo credit: Ben Prowell

Photo credit: Ben Prowell

14-4—-PROGRESS

Oftentimes we’ll create a tenon with a single haunch, providing an added shoulder as well as reducing the proximity of the tenon to the top of the stile that will eventually be cut to the arch of the top rail. Other times we’ll simply divert the profile of the top of the stiles to accommodate a full tenon, such as #14-4.

14–PROGRESS

Ben driving the wedges into place. With each tap, the joint tightens. When the joint is installed and the moisture of rain or humidity are absorbed, the joint tightens even further.

14-4—-PROGRESS

Showing the thru-tenon and wedges being cut flush. The wedges are quarter-sawn white oak.

More on Prowell’s Joinery

14-4—-PROGRESS

The finished joint.