PEAKED WOOD DRIVEWAY GATES 16

Driveway Gate 16 is Base Price + 15%

> Go to Base Price Table

16-3

16-3

Base Price + 15%

GAVLE WOOD DRIVEWAY GATE 16-3

Croton-On-Hudson, New York

Peaked wood driveway Gate #16-3 along the Hudson Valley of upstate New York. Featuring a gabled top rail.

Approximately 5″ grid openings.

16′ overall opening. Option #3 w/embedded steel frame.

Shown with:

- Garden Gate Style 52

- Lighted Columns, Click Here

- Flanking Panel Style 22

PEAKED WOOD DRIVEWAY GATES #16-3

Croton-On-Hudson, New York

![]()

#16-4

#16-4

Base Price + 15%

GABLED WOOD DRIVEWAY GATE #16-4

Mill Valley, CA

The Prowell gabled wood driveway gate 16 with a recently restored Craftsman home in Marin County, CA.

GABLE WOOD DRIVE GATES 16-4

Mill Valley, CA

PEAKED DRIVEWAY GATES WOOD 16-4

Mill Valley, CA

An unusual departure showing the custom wood driveway gate set to a higher height than the adjoining pedestrian gate and panel. Viewed as if approaching from the street. Because the driveway slopes uphill toward the property, the gates consequently open out toward the street. In doing this, the motors are mounted on the street side, pulling instead of pushing the gate open. Were they to mount the motors on the property side and out of view from the street, the gate opening would lose approximately 8″ clearance per gate to accommodate the added elbow in the motor arm.

We show an armature style motor. These are easy to install, with one end mounting to the post and the other bolted through the bottom gate rail. They are rated at 750 lbs. For more information on Armature motors, and links to purchase on-line, see the Product Specifications page Here.

Another option is the “in-ground” operator Viking I-8, which rests beneath the gate with a pin hinge system. A popular system with a low visual profile that is approximately twice the cost of an armature motor. Information on these can also be found on the Specifications Page.

Shown with pedestrian gate style #52 and flanking fence panel style #22.

WOODEN DRIVEWAY GATES 16-4

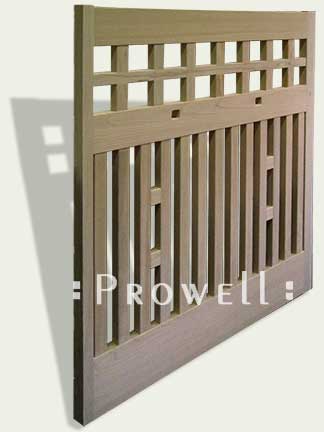

A close-up look at the workmanship and joinery involved with the driveway gate 16. Approximately 4-1/2″ grids.

WOODEN DRIVE GATES 16-4

![]()

#16

#16

Base Price + 15%

CUSTOM WOOD DRIVEWAY GATE #16

Miami, Florida

A pair of wood driveway gates 16 in southern Florida. With existing stone columns that were old and structurally weak, new 6×6 steel posts were installed behind the existing stone.

West Entrance

In Miami and southern Florida, solid panel driveway gates are not within hurricane codes.

Approximately 6″ grid openings.

CUSTOM WOOD DRIVE GATES 16

Miami, Florida

South Entrance

More old stone columns, with the driveway gate supported by new steel posts hidden behind the columns. With drive gates such as both the west and south entries, where the main residence is far beyond the visible scope of approaching visitors, Call-Boxes are utilized. These are either on a stand 7-10 feet street-side for in-swinging gates to allow access from a car window. Or they are mounted to a column and must be approached on foot. Either way, the purpose is to allow your visitors to announce themselves and with the gate automation wired to the house or your phone, the gate can be released. To avoid the expense of trenching wiring to the house, folks will often opt for a keypad access, mounted to the columns and allowing known visitors to enter a code for access (including the fire dept).

The simplest, most affordable means of drive-gate automation access is to have the motors configured to either a remote, or your cell phone. This same code can also be configured for the garage doors, eliminating a slew of remotes stashed in the glove compartment.

ACCOMPANYING GARDEN GATE 52

Miami, Florida

At the south gate we look at the Prowell Gate Column wrapping a 6×6 steel post separating the Driveway Gate from the Pedestrian Gate.

In such examples, where the driveway gate is supported by the needed steel post, the post can be left exposed, or painted to match the gates, or wrapped with a Prowell Column. Wrapping a steel post on site by an installer using 1x material and butt joints will almost always cup and check, as this solution is not designed to allow the wood to expand and contract. Hence the Prowell Columns are built with the same methods as the gates. On the left we see the call-box/keypad mounted to the Prowell column. We also can see the exposed steel frame required by Prowell when overall widths are beyond 12′ and also required for Florida hurricane code. The steel frame will eventually be painted to match the gates.

Showing Garden Gate Style 52, with the modified gable top rail.

![]()

16-1

16-1

Base Price + 15%

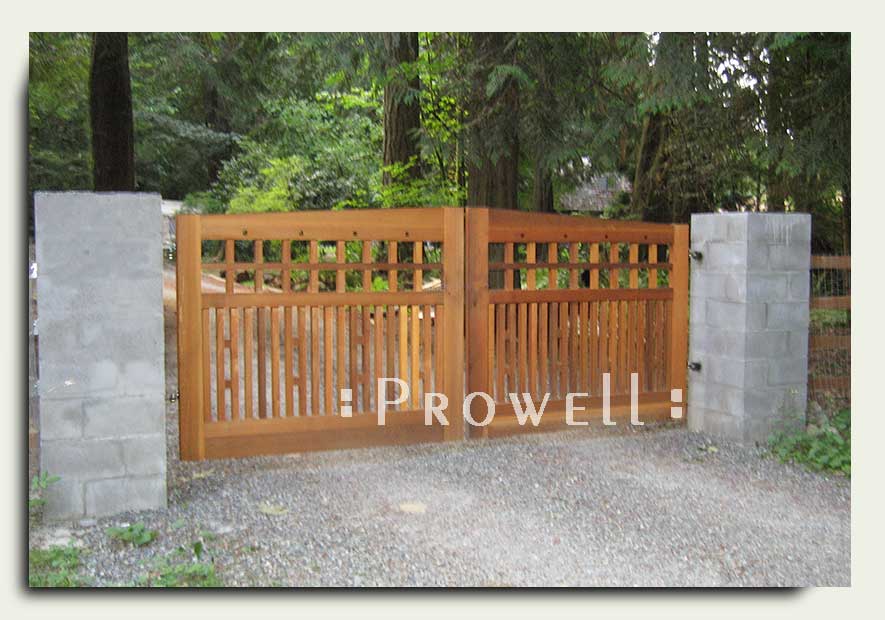

BI-PARTING WOOD DRIVEWAY GATE 16-1

Mill Valley, CA

The original drive gate 16 in Marin County, California., Photographed approximately 12 years after the 1996 installation. Showing a pair of odd, towering twin columns. A generally wooded, isolated homestead required an open design.

A steep, almost unnavigable uphill driveway, requiring out-swinging Wood Driveway Gates and motor arms mounted to the street side, pulling the single-span gate open toward the street. (Single span swings require an exposed steel frame to which a pair of gates mount onto, with the steel frame visible on the property side only.)

Most local codes require our Driveway Gates, whether in-swings or out-swings, to be set at least 12′ back from the sidewalk or street. The reasoning is to prevent the homeowner from stopping traffic while waiting for their automated Gates to open, but also, with out-swings, to prevent them from opening onto the sidewalk or street. It also allows fire trucks the ability to pull into the drive. Many local codes with homes on trafficked streets require the gates be within 150 feet of the residence, or basically a distance that allows the fire hose to reach a burning house from a closed gate in the event no one is home and the firemen are unable to open the gate.

Approximately 7″ grid openings.

![]()

16-5

16-5

Base Price + 15%

ENTRANCE DRIVE GATE 16-5

Berkeley, CA

Shown as a single span. 10′ 4″ rough opening.

CUSTOM WOOD DRIVEWAY GATES 16-5

Berkeley, CA

Showing the exposed steel frame and armature motor, sufficient for a single-span drive gate with a steel frame.

Why only a few select styles extending beyond our normal 6′ maximum width?

Once the final assembly process begins, joining the upper grid and the lower pickets to the three rails begins on one end in a race to the other other end without the glue setting on those first joints. In the below gate, the final assembly involves fitting 34 joints in the grid pattern and 77 lower picket joints, as well as the six primary stile-to-rail joints. All before the glue on the first joints begins to set up.

Followed by the issue of how exactly to get this 12′ package to you. If it’s a delivery, we must hired a special truck or class C trailer. If it’s shipped, we must build an upright crate that can be maneuvered onto the UPS lift-gate (at 8′ width) with a forklift.

And lastly, we generally work with two workbenches in the shop, such that two projects can be underway at any given time. Gates of an inordinate width require the use of both benches at once.

16-6

16-6

Base Price + 15%

DRIVEWAY GATES WOODEN 16-6

Issaquah, Washington

As an incomplete installation, with the gates in place and the columns yet to be clad in stone.

At 12′ overall, no steel frame. Nor our standard jambs mounted to the columns, with the hinging as adjustable eyelets welded to the column steel core.

![]()

IN-PROGRESS

DRIVEWAY GATES 16-5—PROGRESS