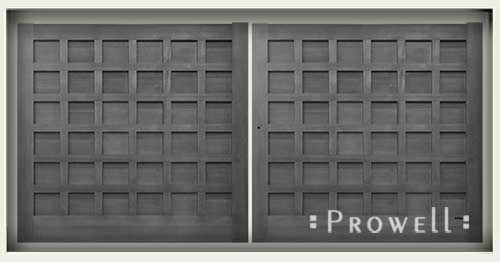

WOOD PANEL DRIVEWAY GATES 7

Driveway Gates 7 is Base Price + 43%

> Go to Base Price Table

DRIVE GATE with SOLID WOOD PANELS 7

Featuring 7″-8″ solid grids

Note: Drive gates #7 is lumber-heavy, requiring a steel frame for overall rough opening widths over 10′.

Born from the original style designed as a pedestrian gate style #87, the wood driveway security gates #7 features a dedicated series of interlocking grids with solid, floating panels. Identical on both sides.

*This is not a piece of plywood with strips of wood nailed in place.

WoodRX Mahogany.

DRIVEWAY SECURITY GATES 7

Showing the side of theprivacy wood driveway gates 7 facing the street.

Gate thickness: 2-1/4″

Horizontal / vertical grid dividers at 1-1/2″ thickness.

Insert panels: 3/4″ thickness

![]()

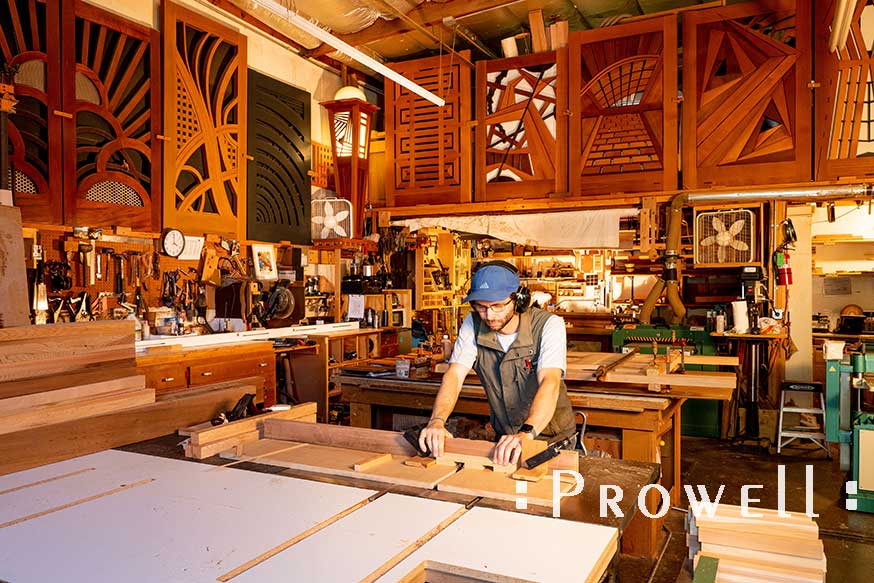

SOLID WOOD DRIVEWAY GATES 7 IN-PROGRESS

Dadoing the intial step to the half-lap joints for the solid grid panels.

photo credit: Ben Prowell

photo credit: Ben Prowell

7–PROGRESS

Ben creating the end-cut joints for the typical wood driveway security gates 7.

7–PROGRESS

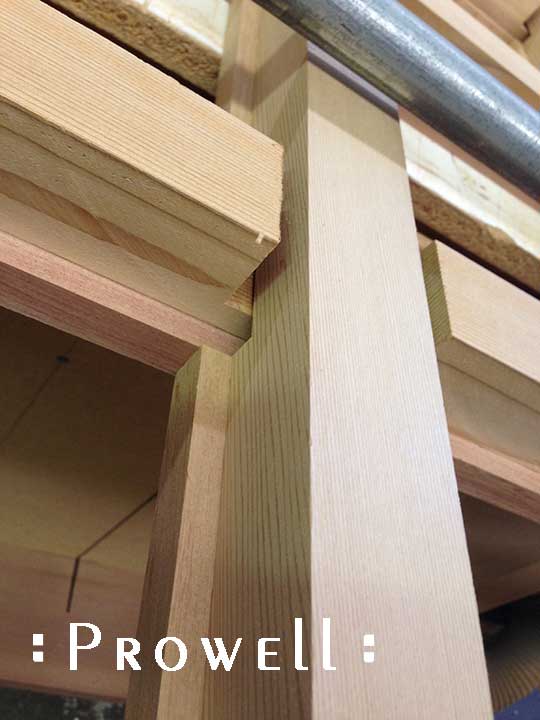

Dry-fitting the cross-members grids. A rather complicated process, showing the dadoes for the half-laps solid panels as well as the rabbets to accept the panel inserts. The property side of the gate prior to fitting the continuous ‘stops’.

7–PROGRESS

Each solid grid panel has a drainage hole, as well as troughs to collect the moisture of heavy rains while migrating to the drainage.

Each grid divider of the wood privacy gates #7 is joined to the stiles and rails of the gate frame with full mortise and tenon joinery.

7–PROGRESS

The top and bottom rail assembled prior to the two vertical stiles. The four outer solid panel insets are set to place, with all the remaining panels placed only after the stiles have been clamped in place. As a privacy gate, #7 is one of the more labor intensive designs.

7–PROGRESS

The top rail fitted and joined to the grid. Showing the stub of the full through-tenon prior to being joined to the vertical stile. The kerfs in the tenon are to accept the eventual wedges, which will separate the tenon to an even tighter fit. The through-tenons are secured in the rails with two locking pins set in through the dado of the rail.

The bottom right showing the thru-tenon, kerfed to accept the locking wedges once fitted to the vertical stiles.

7–PROGRESS

Charles fitting the wedges to the full through-tenon of driveway gate 7.

See Prowell Joint #9

7–PROGRESS

The endless solid insert panels as the signature for the wood driveway security gates #7, each of them sealed with a lifetime emulsified liquid wax to prevent the potential of checking and unnecessary absorption of moisture.