CUSTOM WOOD DRIVEWAY GATES 31

Driveway Gates are Base Price + 24%

> Go to Base Price Table

CUSTOM WOOD DRIVEWAY GATES 31

Mill Valley, CA

Driveway security gates 31-2 features 3 rows of upper grids. Equally spread across the width and height of the grid pattern. Grid sizes at 5.48″ each. Smaller, or larger, grids are available.

Grids are calculated off the net gate widths.

WOOD DRIVEWAY SECURITY GATES 31-2

Mill Valley, CA

Driveway gates that swing out toward the street are required by most codes to have a 12′ set-back from the sidewalk.

Here we see heavy-duty strap hinges, provided by the site.

Also the cane bolt, exposed to the street view–Not sure why they have elected to install a cane bolt, which are normally restricted to manual-swing gates.

The bottom clearance is less than optimal and would be best at 2″ between the gate and the grade.

DRIVEWAY GATES WOODEN 31-2

Mill Valley, CA

One year later, gradually weathering to a silvery gray. The armature automation motors in this example have been mounted on the property side and to the middle rail. As drive gates that swing out toward the street, the advantage is not having the motors visible from the street. The disadvantage is when mounting motors on the inside for out-swing gates, you lose approximately 4″-6″ clearance per motor armature.

For more on Driveway Gate automation and the various options, see Product Specifications by Clicking Here.

![]()

31-1

31-1

Base Price + 19%

WOOD DRIVEWAY ENTRANCE GATE 31-1

Red Bank, New Jersey

(4 rows of grids)

Wood driveway gates 31-1 was part of an extensive fence-line in New Jersey. Because the gates and fence panels all share the same grid sizes, but different net widths, the grid pattern on the driveway gate shows the remainders on the right and left side of each gate. Grid sizes 4.02″ each.

WOODEN DRIVE GATES 31-1

Red Bank, New Jersey

Our first thought: Vintage pillbox architecture, opting for the Fence Style 25 and Drive Gates Style #31, with their upper square grids mimicking both the Box floor plan and the prominence of the top bank of windows.

The back yard fronting the Navesink River.

WOOD DRIVE GATE -OPEN GRIDS 31-1

Red Bank, New Jersey

Showing the flanking side Panels Style 25 that were installed the previous spring already weathered to a silvery gray. The driveway gates, more recently installed, will age to the same patina.

![]()

IN-PROGRESS

31–PROGRESS

Shop Views–2017

An embedded-steel drive gate 31 fully assembled. 3″ thickness.

More on Option #3 Embedded Gates: Click Here

31–PROGRESS

Shop Views–2017

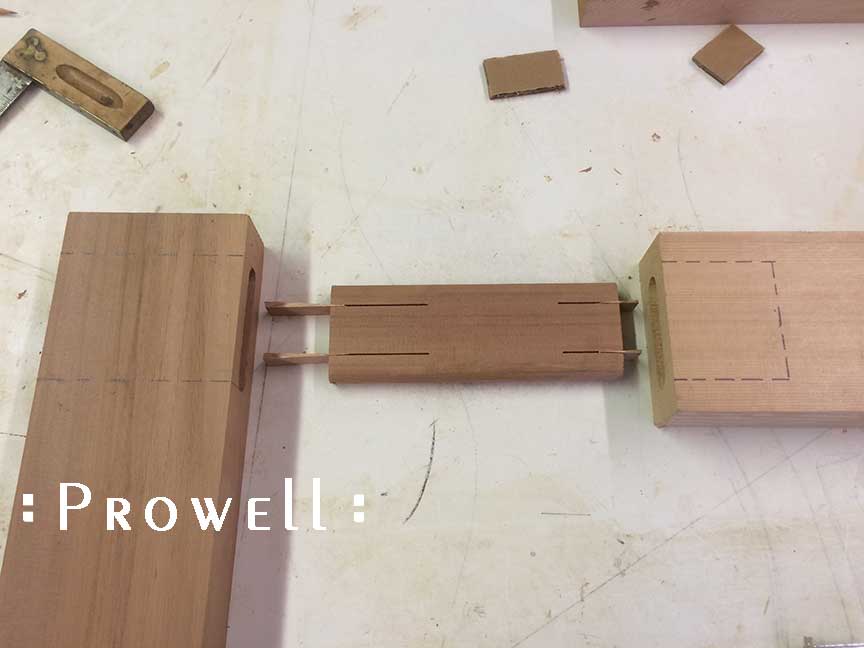

Although the joinery varies widely, we’ve opted for this 12′ overall opening without steel what might be called a ‘Thru floating mortise and tenon with expanding oak wedges in both the exposed hinge stiles, as shown below, as well as blind wedges within the tenon-to-rail mortise’. A mouthful.

31–PROGRESS

Shop Views-2018

Charles cutting the top tenon flush.

31–PROGRESS

31–PROGRESS

Shop Views-2017

Let’s go ahead with a few explanatory images that will at once be of interest to you, our potential patron, while also spoon-feeding the legions of aspiring competitors toward the secret sauce that, in part, accounts for why this gate will last around 50 or so years, or until some unlikely event like a wayward comet makes its landfall at the foot of your property. And it should be noted, here and now, that we charge for rebuilding any and all gates obliterated by, well . . . by wayward comets.

The basic premise shown below.

31–PROGRESS

Shop Views

The exposed Thru-Tenon and Wedges on the vertical stiles at the bottom of the image serve to expand the tenon against the shoulders of the mortise with a permanency that will, with exposure to dew and fog and rain and humidity, expand and become even tighter. While in the drier season, the joint will shrink back to the original fit created in the shop.

31–PROGRESS

Shop Views

The blind wedges shown as they feed into the 3″ deep mortise in the horizontal rails. As the tenon is tapped in place, the wedges will eventually reach the back of the mortise and with each subsequent tap, they drive themselves into the tenon, expanding the cheeks against the shoulders of the mortise.