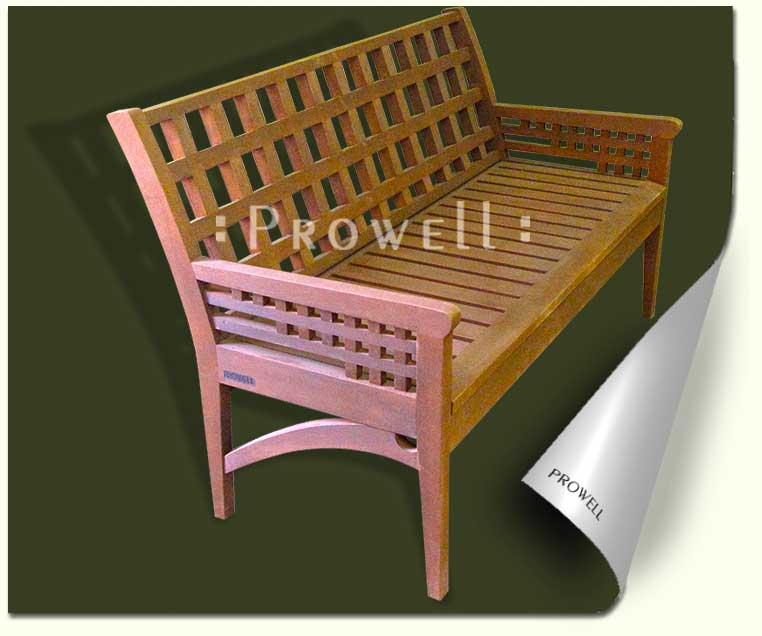

Outdoor Wood Garden Bench #20

Garden Bench #20 is Base Price + 30%

#20

#20

CUSTOM WOOD BENCH #20

Features a 3-1/2″ backrest grid and a graduating pattern armrest of 1″ grids

CUSTOM WOOD BENCH #20

Although the grades of cedar, along with the designed methodology, do not necessarily require a finish, the benches and swings are unlike the gates and fences, etc. They somehow seem incomplete without a finish. Perhaps this is simply due to the fact we sit on benches and swings and unless you’re a bird, sitting on a gate or fence is not so easily administered.

![]()

#20-1

This Bench is Base Price + 30%

>>Go to Base Price Table

CUSTOM WOOD ARBOR #20-1

Sonoma County, CA.

1918 Sears Kit house.

Garden Bench #20 was developed with a deeper seat and an increased slope to the backrest.

![]()

#20-2

This Bench is Base Price + 30%

>>Go to Base Price Table

CUSTOM WOOD ARBOR #20-2

Wood Bench #20-2, where our homeowner in Portland, OR admits to deciding against the back porch in lieu of the breakfast nook.

![]()

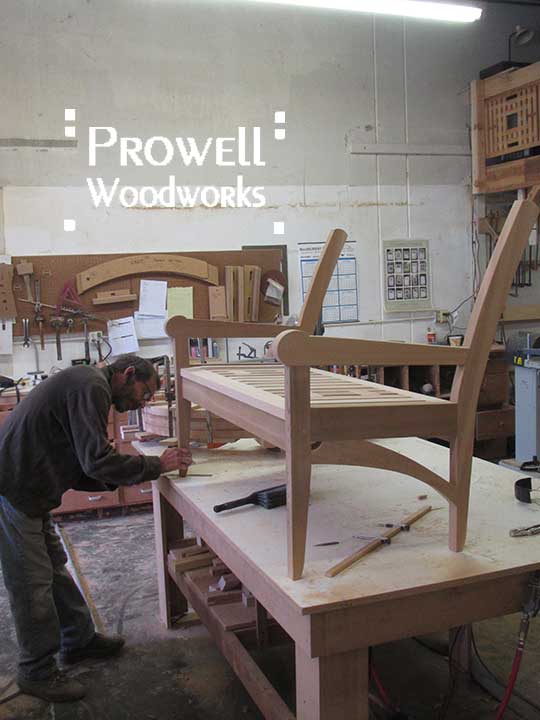

PROGRESS

WOOD GARDEN BENCH #20 PROGRESS

WOOD GARDEN BENCH #20 PROGRESS

Below, the leg assembly, with it’s tenons in place and ready for a dry fit.

BENCH #20 PROGRESS

WOOD GARDEN BENCH #20 PROGRESS

The leg assemblies for the Wood Garden Bench. The pattern of small 1″ open grids was borrowed, oddly, from the motif of the Rockefeller Plaza lobby.

WOOD GARDEN BENCH #20 PROGRESS

The seat slats of the wood bench are mortised into a front and rear rail for a total of 38 mortise and tenon joints whose collective strength adds to the lasting integrity of the final assembly.

WOOD GARDEN BENCH #20 PROGRESS

Tapping the tenons into their mortises of the seat rails.

If you can push a tenon into its mortise by hand, it is too loose.

WOOD GARDEN BENCH #20 PROGRESS

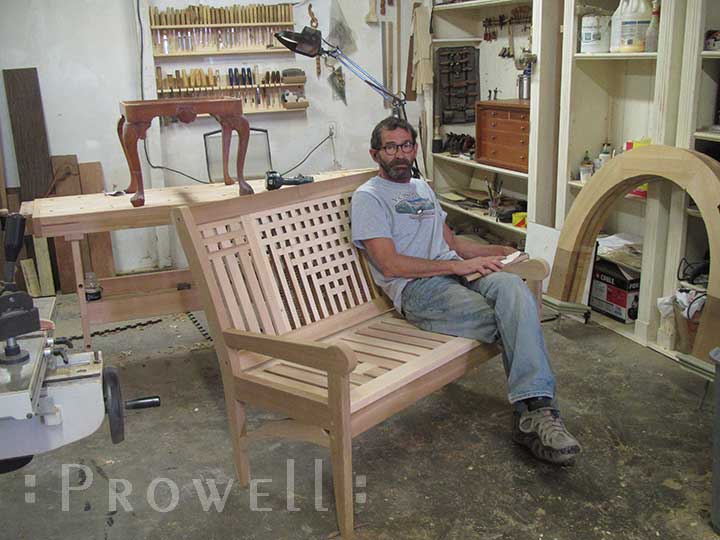

Charles in repose with one of the several bench prototypes that languished for years, under the fussbudget process of revisions and successive drafts before it graduated to the galleries. This is the result of the woodworker losing himself in the process. Having fun. Sometimes too much fun, while surpassing that plateau of what is required to make a living. The Prowell closet of such speculative efforts is stuffed to the brim.

WOOD GARDEN BENCH #20 PROGRESS

The front and rear aprons that are shown clamped to the leg / arm assemblies is an interlocking tenon that alone prevents the Garden Bench from lateral wobbling. A wobbly bench is similar to a sagging gate–defeating the very purpose of us approaching the product in the first place.

WOOD GARDEN BENCH #20 PROGRESS

A few words regarding the relationship between design and workmanship.

Any Outdoor Wood Furniture exposed to the elements, whether on your porch or within your landscape, is going to expand and contract at a much greater degree than those furnishings inside the insulated conditions of your home. It is going to be exposed in a way unlike your front door, or the siding on your house, or the planking on your deck or most certainly the your dining room table–none of which is exposed to 360-degrees of nature. If for no other reason, this constant dimensional shift of the wood requires a methodology other than screws and bolts. As the wood shrinks, you see, the screwhole expands and the threads lose their grip. When you sit on the bench, shifting your weight, the screw / bolt has room to wiggle and with each wiggle the widening hole grows wider. You replace the screws and bolts with longer or larger screws and it holds tight until the following season when the wood shrinks again and the process begins anew.

There are principles of construction required for the structural integrity of outdoor furnishings intended to last interminably. Those principals involve joinery, which involves understanding those principles, which traditionally involves an apprenticeship that requires slightly longer than a weekend. More like years, or in Charles’ case, and Ben’s, decades. Learning the multitude of joints and how to cut them perfectly and snugly, and learning which of those joints is best suited for any given application and from there, innovating new joints not found in any manual, anywhere.

Principles that apply to outdoor benches and swings, but also to virtually every product offered by Prowell Woodworks. And how a garden gate requires a different joint than a fence panel or a pergola or an arbor or even the post caps.

You see, it goes far beyond the designer’s eye, which we’ll add requires the same decades-long apprenticeship as does the workmanship. The design itself is apparent– it’s aesthetic appeal to you and your neighbors and all those who encounter a first impression of these products–whereas the joinery responsible for that work surviving as an inheritance to your heirs remains unseen. Invisible. Easily fudged by supplanting this art with a few store-bought screws and screw gun.

Let’s pretend you’ve managed to corner Charles, or Ben, and in the hard-hitting conversation over a cup of tea, you ask:

–So is there anything that robs you of sleep at night?

–-When someone calls to inform me they have come across our recognizable work in Atlanta or Pittsburgh or Vermont and how, sadly, it is not holding up. It is, in fact, appearing rather shabby. We ask for an address, or a street, and check the database to learn no such work was commissioned at such an address and how the work has been compromised by a 3rd party replication. How the mimicked design falls apart and to others, such as the caller in question, one assumes it is ours and equally associates this with an unwarranted reputation. Works that fall apart. This, oddly, robs me of sleep.

Design is important. Design is the result of talent, education, apprenticeship, and experience and when it works, we have the likes of the Golden Gate Bridge or the Chrysler Building or a power plant dam tucked deep into the north fork of the Feather River designed by someone employed in 1934 by the New Deal’s WPA with little expectation of it being seen and appreciated. Good design is good art and good art is beauty and the impact of beauty cannot be discounted.

But we often overlook the engineers and workman responsible for building the bridge or highrise or power dam, and the principles they employ to insure that the Golden Gate Bridge performs for generations thereafter.

–So that’s it? That’s the only worry you have that might keep you up at night?

–Sleep comes easy and quick. You’re exhausted. You’ve put in a day of being absorbed from start to finish, like any day, and sleep is like spilled molasses; it starts with your legs, spreading up the length of your legs until your legs are numb and then your chest until your chest is numb and then your arms and all the while the brain is more or less awaiting its turn, waiting for the inevitable with no intention of resisting the inevitable and when it comes, when the molasses spreads, the brain has emptied itself with a readiness to go nightie night.

![]()