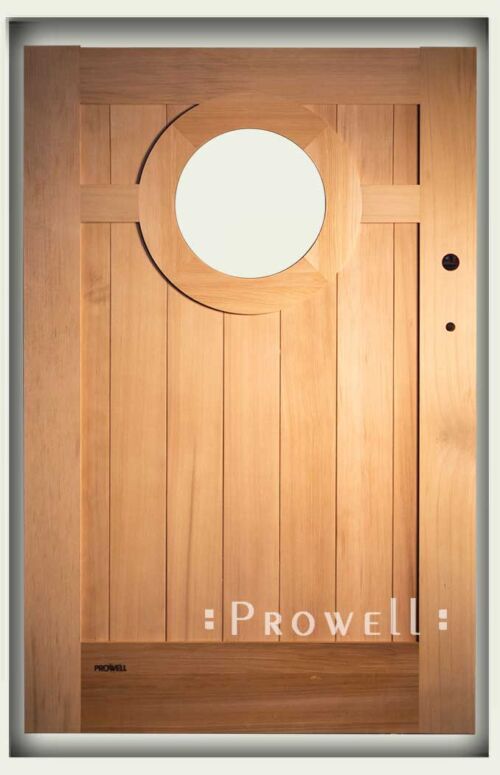

CUSTOM WOOD GARDEN GATE 6

Garden Gate 6 is Base Price + 28% w/o plex

W/plex 36%

Go to Base Price Table

#6-2

#6-2

Base Price + 28%

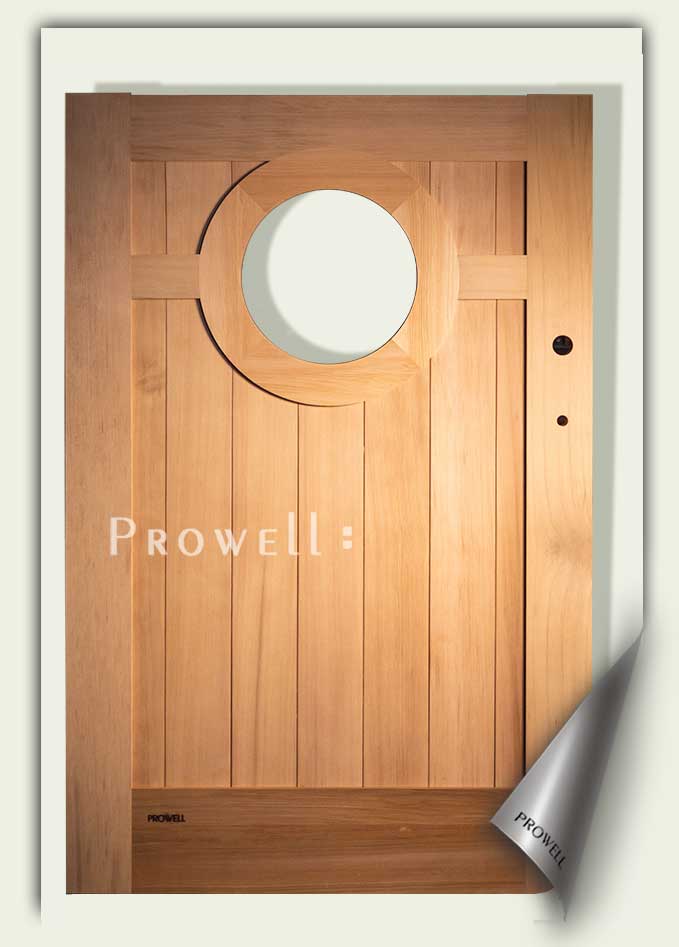

CUSTOM WOOD GARDEN GATE 6-2

Wood gate #6-2 is modified from our Gate Style #2, but with a full radius porthole as an answer to the suggestions of those in the yachting and boating communities. Or any community, it would seem.

As solid panel, shown, or with the open pickets more common to gate style #2. The pricing is the same.

CUSTOM WOOD GARDEN GATE 6-2

![]()

WOOD GARDEN GATE 6

San Rafael, CA (Marin County)

(With plexiglas)

A view through one of the three side entry gates into the backyard area that fronts the San Rafael canal, as an estuary to the San Francisco Bay. A marine setting that prompted the portal circumference of the gate. Prior to the posts being cut to length and the mounting of the Rocky Mountain gate latches.

Wood gate 6 is optional with or without the Plexiglas fill. As a reference: The obscure Plexiglas option shown on the right is from Tap Plastics. #P-95

WOOD GARDEN GATE 6

San Rafael, CA (Marin County)

![]()

#6-1

#6-1

Base Price + 36%

GARDEN GATE 6-1

Los Angeles, CA

Gate 6-1 as an in-progress installation, with the Arbor style #8.

‘White Light Opaque plex.

![]()

#6-3

#6-3

Base Price + 36%

CUSTOM WOOD GARDEN GATE 6-3

Los Altos, CA

Replacing the plexiglas with a solid wood insert.

WOOD GARDEN GATE 6-3

Los Altos, CA

![]()

#6-2

#6-2

Base Price + 36%

CUSTOM WOOD GARDEN GATE 6-2

Montauk, NY

Seemingly a gate going nowhere.

Montauk represents the easternmost point on Long Island, so the gateway may in fact represent the edge of civilization.

Rocky Mountain latch e236 and dead bolt DB312. Silicone bronze medium.

![]()

IN-PROGRESS

Building a strong gate

Los Angeles, CA

Creating the template.

WOOD GATE 6–PROGRESS

Ben routing the Joined segments. The two handles mounted onto the template make for easy, and safe, machining.

GATE 6–PROGRESS

Preparing the dadoes in the stiles. Chisels and mallets.

GATE 6-2–PROGRESS

Set to the left side near the backsaw is the jig that ensures a perfectly mated fit with the portal radius and the top rail.

It’s not uncommon that more time will be spent creating the templates and jigs than making the actual final cut. So what.

GATE 6–PROGRESS

GATE 6-2–PROGRESS

Boring for the latch and dead bolt is best accomplished prior to assembly. Just in case.

<photo credit: Ben Prowell

<photo credit: Ben Prowell

WOOD GATE 6-2–PROGRESS

The dry layout to mark the upper T&G contours for a perfect fit.

photo credit: Ben Prowell

photo credit: Ben Prowell

WOOD GATE 6-2–PROGRESS

The dry layout to mark the upper T&G contours for a perfect fit.

photo credit: Ben Prowell

photo credit: Ben Prowell

WOOD GATE 6-2–PROGRESS

Ready to pencil-mark the final fit

photo credit: Ben Prowell

photo credit: Ben Prowell

WOODEN GATE 6-2–PROGRESS

Because the T&G fits into the dadoes, there is some forgiveness to the preciseness of the cut.

photo credit: Ben Prowell

photo credit: Ben Prowell

WOOD GATE #6-2–PROGRESS

Because the T&G fits into the dadoes, there is some forgiveness to the preciseness of the cut.

photo credit: Ben Prowell

photo credit: Ben Prowell

GATE DESIGN 6-2–PROGRESS

The upper T&G pieces cut and ready for assembly.

photo credit: Ben Prowell

photo credit: Ben Prowell

WOOD GATE #6-2–PROGRESS

The upper T&G pieces finally assembled.

photo credit: Ben Prowell

photo credit: Ben Prowell

WOOD GATE 6-2–PROGRESS

Fitting the planks in place

photo credit: Ben Prowell

photo credit: Ben Prowell

GATE 6-2–PROGRESS

Set to the left side near the backsaw is the jig that ensures a perfectly mated fit with the portal radius and the top rail.

It’s not uncommon that more time will be spent creating the templates and jigs than making the actual final cut. So what.

photo credit: Ben Prowell

photo credit: Ben Prowell

GARDEN GATE 6-2–PROGRESS

photo credit: Ben Prowell

photo credit: Ben Prowell